What is the Lubrication Pump?

In the world of machinery and mechanical systems, the proper functioning of various components is crucial for efficient and reliable operations. Lubrication plays a vital role in ensuring the longevity and performance of these machines. One key element in the lubrication process is the lubrication pump. In this blog post, we will explore the importance and functionality of lubrication pumps, shedding light on their significance in various industrial applications.

What is a lubrication pump?

A lubrication pump, often referred to as a grease pump or oil pump, is a mechanical device designed to deliver lubricants (such as oil or grease) to specific parts of a machine or system. The primary purpose of a lubrication pump is to reduce friction, dissipate heat, and protect moving components from wear and tear. Without adequate lubrication, machines can suffer from increased maintenance needs, decreased efficiency, and even premature failure.

Lubrication pump is a lubrication equipment, lubricant supply to the lubrication part. Mechanical equipment need regular lubrication, before the main way of lubrication is according to the working condition of the equipment, to reach a certain maintenance cycle for manual lubrication. Lubrication pump can make this maintenance work easier. Lubrication pump is divided into manual lubrication pump and electric lubrication pump.

Automatic lubrication device can effectively reduce equipment failure, reduce energy consumption, improve productivity and extend the service life of the machine.

A variety of specifications of the distributor, to realize the various types of friction vice precise oil supply; Combined lubrication valve block, can be convenient to amend the system design, and can be changed according to the production requirements, so as to make the lubricant consumption of the most economical.

Continuous progressive lubrication distributor can withstand 20Mpa pressure, can be a distance delivery of lubricant, its advanced structure effectively prevent the lubricant due to self-weight backflow.

The oil supply lubrication components are well manufactured, with perfect performance and first-class quality, which are essential for maintenance-free centralized lubrication system. Multi-functional monitoring components can accurately and timely monitor the operating conditions of each lubrication point (friction vice) and report the faulty parts of the machine.

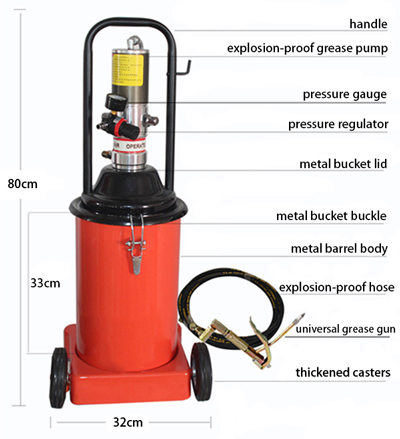

Structure and working principle3 gallons air grease pump

Lubricating oil pump is mainly composed of pump body, gears, shafts, bearings, front cover and back cover, sealing parts, coupling and other components. There are two forms of shaft end seals: packing seal and mechanical seal.

When the meshing gears rotate in the pump body, the gear teeth keep entering and exiting to mesh with them. In the suction chamber, the gear teeth gradually exit the meshing state, so that the volume of the suction chamber gradually increased, the pressure is reduced, the liquid under the action of the liquid surface pressure into the suction chamber, with the gear teeth into the discharge chamber. In the discharge chamber, the gear teeth gradually enter into the meshing state, the gear teeth are gradually occupied by a gear teeth, the volume of the discharge chamber is reduced, the liquid pressure inside the discharge chamber rises, so the liquid is discharged from the pump outlet is discharged out of the pump, the gears continue to rotate side by side, the above process continues to take place, the formation of a continuous oil transfer process.

Lubrication pump types

Lubrication pump, manual lubrication pump, electric lubrication pump, pneumatic lubrication pump, oil supply pump, automatic lubrication pump, hydraulic station, lubrication pump station, oil mist lubrication, oil and gas lubrication, lubrication device. With more than eighty product series of more than 600 specifications of lubrication devices, lubrication systems, lubrication components, oil supply systems, such as a full range of lubrication machinery products and ancillary parts.

Lubrication pump supporting equipment

Proportional, quantitative, progressive and other three categories, covering the full range of dry and thin oil lubrication products, involving the following systems: SLR lubricant (grease) single line damping centralized lubrication system, PDI lubricant (grease) volumetric centralized lubrication system, PRG lubricant (grease) progressive centralized lubrication system, oil mist lubrication lubrication system, oil-air lubrication lubrication system, automatic lubrication system of the vehicle chassis, the assembly line air-controlled precision quantitative lubrication device, open-air lubrication system, lubrication system, lubrication system and lubrication equipment. Precision quantitative oil supply device, open gear lubrication device, chain lubrication device, special equipment lubrication device, various types of special hydraulic pump station. Form: manual lubrication pump, electric lubrication pump, pneumatic lubrication pump, numerical control lubrication pump, automatic lubrication pump, intelligent lubrication pump. With more than eighty product series of more than 600 specifications of lubrication devices, lubrication systems, lubrication components, oil supply systems and other full range of products and ancillary parts.

Lubrication pumps are unsung heroes in the world of machinery and industrial systems. They ensure that equipment runs smoothly, efficiently, and safely by providing the necessary lubrication to moving parts. Understanding the significance of lubrication pumps in various applications is essential for anyone involved in the maintenance and operation of mechanical systems. These devices not only extend the lifespan of machinery but also contribute to cost savings and improved overall performance. Various lubrication pumps are available in the ATO store and can be purchased if necessary.