5 Major Factors Affecting Slip Ring Service Life

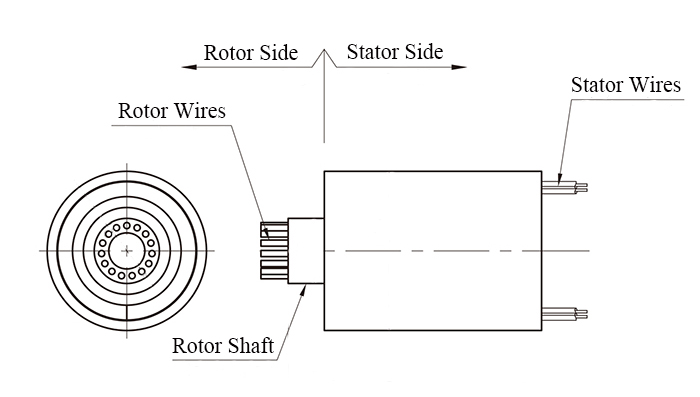

Slip rings are used between any electrical components that rotate 360° relatively continuously to transmit functional power sources, weak electrical signals, light signals, air pressure, water pressure, oil pressure, and other different energy medium. Slip ring is precision transmission device, so users should understand the factors that affect slip ring service life, so as to avoid unnecessary waste and maintain the normal operation of equipment.

1. Slip Ring Material

As we all know, when the slip ring is running, stator and rotor are transmitted by friction. Therefore, selection of wear-resistant materials is very important. In general, precision slip rings are made of multiple alloy materials because of their good wear resistance and good electrical conductivity. For the insulating material, original material is usually used to prevent the secondary use of recycled material, which is beneficial to the guarantee of insulation performance. For shell part of slip ring, good aluminum alloy material or high-quality stainless steel material is usually selected, which has good strength and strong manufacturability.

2. Slip Ring Using Environment

Although we have to admit that the service life of slip ring has a great relationship with the manufacturer's production technology and production materials, in many cases, the use of slip ring also determines length of its life. Generally speaking, service life of a slip ring which is properly used and maintained is 5-10 years. On the contrary, if the slip ring is used in a humid, high temperature, high pressure, and corrosive environment for a long time, its life will be greatly shortened. Therefore, when using the slip ring, it is best to place it in a ventilated place away from high temperature and high pressure, so as to avoid unnecessary waste and normal maintenance of equipment operation.

3. Slip Ring Overall Structure

In order to make it easier for customers to install slip rings, manufacturers design slip rings of different structures according to the type of installation equipment: through hole slip rings, rotary joint, cap slip rings, disc slip rings, separated slip rings and so on.

Customers can make different choices according to the requirements of slip rings. Due to different structure of slip rings, service life is also different, and the service life of slip rings modified by through hole slip rings will be longer.

4. Slip Ring Revolving Speed

Slip ring itself has no speed and its own torque is small. It relies on mechanical equipment to drive the slip ring to rotate. According to the working speed of customer's mechanical equipment speed, and internal structure and performance characteristics of the slip ring, operating speed of the slip ring with different structure types is different. When using slip rings, working speed of the mechanical equipment must not be greater than the set speed of slip rings, otherwise service life of slip rings will be affected. For slip rings with different sizes, the ring channel and wire are directly rubbed during work. The linear speeds corresponding to the same working speed are different. The larger the ring channel, the greater the wear on slip ring, and the service life is relatively reduced.

5. Slip Ring Assembling Technology

For customized slip rings, it is firstly required to ensure the completeness and correctness in the design of the product drawing, analyze structural technology of the product, and clarify assembly relationship between slip ring and installation equipment. Secondly, under the premise of guaranteeing slip ring quality, efforts shall be made to improve its quality to achieve its service life. Finally, specification test for the slip ring can better reflect comprehensive performance of slip ring, and timely find and solve problem. Tested specifications include slip ring appearance structure test, normal life test, static contact resistance, dynamic contact resistance, insulation resistance, dielectric strength and friction torque inspection, etc.

How to prolong slip ring service life

- During installation of the slip ring, a reasonable radial clearance has a great impact on slip ring service life. When radial clearance of the slip ring increases, its load area decreases and the maximum rolling load increases, thereby reducing slip ring service life.

- If the environmental cleanliness does not reach a certain level, it will cause dirt on the metal ring surface of slip ring or increase the virtual contact or resistance value (except for special slip rings, such as slip rings with high protection requirements).

- Please use slip rings in dry, no corrosive gas, no strong acid, and no strong alkaline places to prevent metal parts from rusting and reduce the insulation performance of electrical components. Avoid using slip ring in high temperature and low temperature environment for a long time. Generally, the working temperature of slip ring is -30℃~80℃, beyond this range, slip ring service life will decrease rapidly, or even cause direct damage.

- Adjust the contact between brush wire of the slip ring and the ring groove. It is better to make the brush wire be well pressed on ring groove without affecting rotation of the slip ring. If the pressure is not adjusted, it will cause virtual contact and insufficient pressure. If the pressure is too large, it will increase the frictional moment, abrade the contact part, and shorten service life of the slip ring.

- Avoid making the slip ring withstand external gravity shock, otherwise slip ring will deform and affect its internal structure.