Explosion Proof Solenoid Valve vs. General Solenoid Valve

Solenoid valve is a kind of industrial equipment controlled by solenoid. It is a basic component for automatically controlling fluid. It belongs to the actuator, not limited to hydraulic and pneumatic. It is used to adjust the direction, flow, speed and other parameters of medium in industrial control system. The solenoid valve can cooperate with different circuits to complete the expected control, ensuring the accuracy and flexibility of the control.

There are many kinds of solenoid valves, different solenoid valves have different functions. In this article, ATO industrial automation will give you a comparison of explosion proof solenoid valve and general solenoid valve.

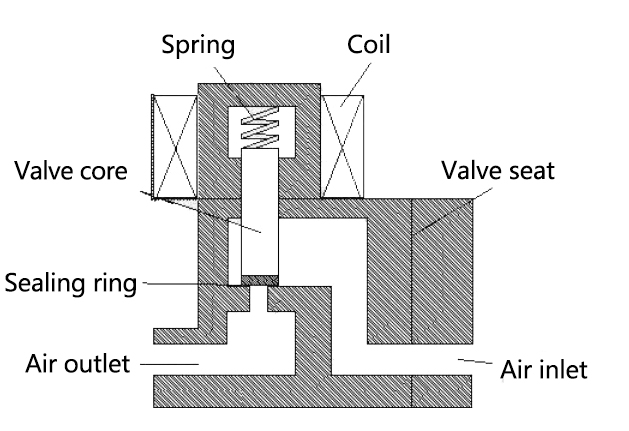

Working Principle:

There is a closed cavity in the solenoid valve with through holes in different positions. Each hole is connected to a different oil pipe. The center of the cavity is a piston. There are two electromagnets on both sides. The magnet coil on which side is energized will be attracted to the valve body.

On either side, by controlling the movement of the valve body to open or close the different oil discharge holes, and the oil inlet is normally open, the hydraulic oil will enter the different oil discharge pipes, and then the piston of the cylinder will be pushed by the oil pressure. The piston drives the piston rod, and the piston rod drives the mechanical equipment. In this way, the specific mechanical movement is controlled by the current switching of the electromagnet.

Wiring Box:

The difference between the general solenoid valve and the explosion proof solenoid valve is reflected in the wiring box. The so-called anti-riot is that the current caused by the electromagnetic head lock is not strong enough to light the corresponding environmental gas, and the simple point is that the energy required by the electromagnetic head action is exposed to the combustible gas. Explosion-proof solenoid valve is set fire to blasting gas mixture components all equipment may be enclosed in a shell, the shell can withstand any joint surface or structure space through the shell, a flammable mixture infiltrate into the inside of the shell in the internal blasting damage, and won't cause external formed by a, multiple gas or steam blasting environment on fire, Put parts that may cause sparks, arcs and dangerous temperatures into the flameproof enclosure, which separates the internal space of the equipment from the surrounding environment. There is a vacancy in the flameproof shell, because of the breathing effect of electrical equipment and the gas penetration effect, so that there may be blasting gas mixture inside.

Advantages:

Explosion proof solenoid valve. It has a long operating life. Explosion-proof solenoid valves are all long-term operation systems, that is, the coil allows long-term energized operation. Regarding the long-term valve registration only needs to be closed for a short time, normally open solenoid valve should be used.

General solenoid valve. Solenoid valve response time can be as short as a few milliseconds. Because of the self-loop, more sensitive than other control valve reaction. Part of the general solenoid valve coil power consumption is very low, energy saving products. General solenoid valve size is small, save space and beautiful. The structure of the electric solenoid valve is easy to control the internal leakage until it is reduced to zero. Therefore, the use of solenoid valve is particularly safe, especially suitable for corrosive, toxic or high and low temperature medium.