Heavy Duty Connectors Working Principle

Heavy duty connectors are widely used in the industrial field as electrical connectors, usually used to connect high current, high voltage, and data signals, heavy duty connectors have strong performance and reliability and are suitable for harsh environmental conditions. ATO online shop will discuss in depth the working principle of heavy duty connectors, the working process, and the advantages.

Principle of Operation

The operating principle of heavy duty connectors is based on several design features that enable them to provide reliable electrical connections in industrial environments.

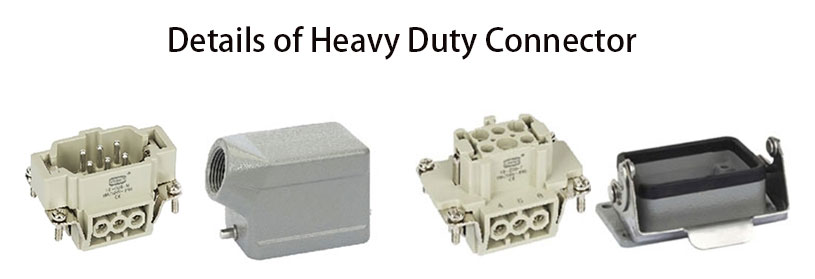

Heavy duty connectors are typically designed with pins and slots to ensure a proper and stable connection. The pins are part of the heavy duty connector and the slots are located on the opposite side of the connector. When two connectors are inserted, the pins are precisely aligned with the slots to ensure a proper connection. Heavy duty connectors typically have excellent sealing properties to resist the ingress of dust, water, and other harsh environmental elements. This sealing performance is usually achieved by a rubber seal or dust cap to protect the electrical components inside the connector.

Heavy duty connectors are designed to handle higher currents and voltages than typical electrical connectors. This means that heavy duty connectors can be used to connect high power devices such as electric motors, actuators, and other high power industrial equipment. Heavy duty connectors are typically able to withstand vibration, shock, and other mechanical stresses because heavy duty connectors are often used in transportation equipment or in industrial environments where vibration and shock are high. This type of connector usually supports multiple plugs, making it possible to connect multiple cables or harnesses at the same time. This is useful in industrial control systems to reduce the number of connection points, improve maintainability, and reduce failure rates.

Work Process

- Connection Preparation: Before using a heavy duty connector, it is necessary to ensure that the pins and slots of the heavy duty connector are clean and that no substance or corrosive material is attached to them. This ensures good electrical contact.

- Inserting the Connection: Insert one side of the heavy duty connector into the other side, making sure that the pins and slots are accurately aligned. Typically, the connector has a locking mechanism to ensure that the connector remains stable after insertion and does not come loose accidentally.

- Electrical Connection: Once a connector is inserted and locked, current and voltage can be passed between the connectors. The design of the pins and slots ensures stable electrical contact to prevent resistance or disconnection.

- Sealing Performance: The sealing performance of heavy duty connectors ensures that the electrical components inside are protected from harsh environments. This sealing performance is a key feature in industrial applications.

- Disconnecting: When it is time to disconnect, the heavy duty connector can be unlocked and pulled out. This process often requires care to ensure that the pins and slots are not damaged, thus maintaining the reusability of the heavy duty connector.

Advantages

Heavy duty connectors offer several advantages that make them very popular in industrial environments.

- High Reliability: Due to their rugged design and sealing properties, heavy duty connectors offer excellent reliability in harsh industrial environments. Heavy duty connectors are capable of stable operation for long periods, reducing the need for maintenance and troubleshooting.

- High Current and Voltage Carrying Capacity: Heavy duty connectors are suitable for high power devices because heavy duty connectors can handle higher currents and voltages without interference from electrical problems.

- Multi Plug Support: Designs that support multiple plugs make it possible to connect multiple harnesses or cables, reducing the number of connection points and improving the overall maintainability of the system.

- Vibration and Shock Resistance: Heavy duty connectors can function properly in environments with high levels of vibration and shock, making them suitable for use in transportation equipment and other applications where stable connections are required.

- Wide Range of Applications: Heavy duty connectors can be used in a variety of industrial applications, including manufacturing, mining, automotive, aerospace, and more. Heavy duty connectors are suitable for a wide range of environments, from deserts to wet harbors.

- Easy to Install and Maintain: Heavy duty connectors are designed to be easy to install and maintain. Accurate alignment of pins and slots and locking mechanisms make connections simple while sealing reduces the need for maintenance.

Heavy duty connectors are widely used electrical connectors in industrial applications, and the heavy duty connector operating principle is based on pin and slot design, sealing performance, high current and voltage carrying capacity, vibration and shock resistance, and multi plug support. Heavy duty connectors provide highly reliable electrical connections, are suitable for a wide range of harsh environments, have a wide range of applications, and are easy to install and maintain. This makes heavy duty connectors an integral part of the industrial sector, providing reliable electrical connections for a wide range of equipment and systems.