How does the Pressure Relief Valve Work?

Our lives are becoming more and more modern, and the energy sources we use are becoming more and more diverse. Regardless of whether it is natural gas, coal gas or new energy sources, attention must be paid to prevent leakage. On the one hand, the leaked energy will pollute the environment, on the other hand, it is also a waste of scarce resources. The most important point is that the leaked energy will pose a threat to human health. Therefore, the use of pressure relief valve is very important. It can monitor the pressure in the transportation pipeline at any time to prevent hidden dangers caused by excessive internal pressure. Therefore, its working principle is also everyone should master. This article will introduce the working principle of the pressure relief valve.

What is pressure relief valve?

The pressure relief valve is a safety protection device, usually used to control the pressure in the hydraulic system to ensure that the system will not be damaged or explode due to excessive pressure. Its main function is to maintain a constant pressure in the hydraulic system and prevent the system pressure from being too high.

The set pressure of the pressure relief valve can usually be adjusted by adjusting the tightness of the spring, and some advanced pressure relief valves can also realize pressure adjustment through electronic control. In hydraulic systems, pressure relief valves are usually installed at the outlet of the system to ensure that the pressure in the system does not exceed the set value.

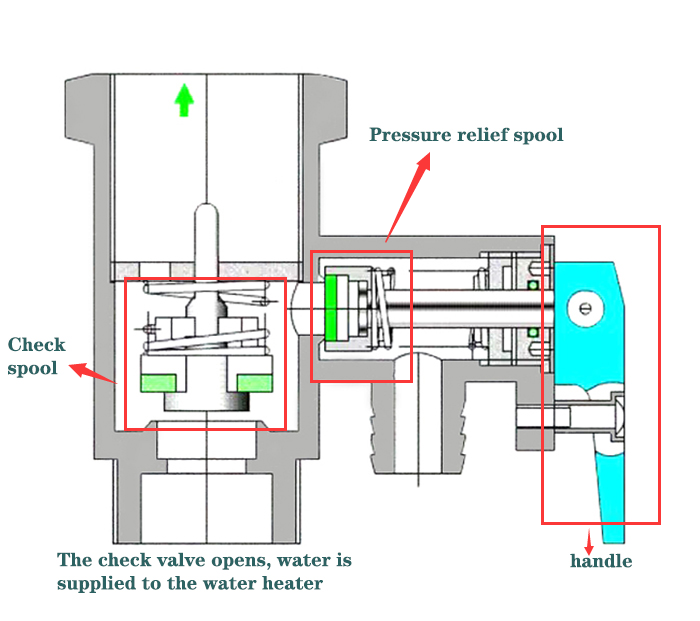

The pressure relief valve is composed of needle valve, pressure gauge, main valve, pilot valve and connecting pipe and other components. It is a kind of hydraulic control valve. The main valve is divided into upper and lower parts by the diaphragm. The lower cavity of the diaphragm is the water flow channel, and the upper cavity is the control room, which controls the opening and closing of the main valve disc. The pilot valve itself is a pressure relief valve, and it also has a control room and a water flow channel, and the opening and closing of the disc is controlled by the control room. The needle valve is the throttle valve, which controls the flow of water in the connecting pipe.

Working principle of pressure relief valve

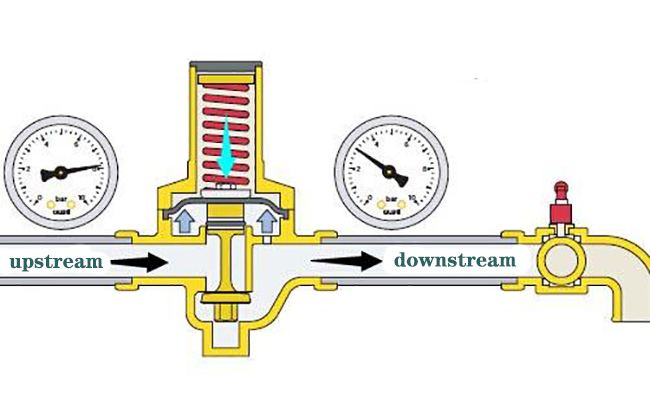

The working principle of the pressure relief valve is based on pressure control. When the pressure in the hydraulic system exceeds the set value, the pressure relief valve will automatically open to release the excess pressure to keep the pressure in the system within a safe range. Pressure relief valves typically consist of a spring and a spool. When the pressure in the system exceeds a set point, the spring is compressed and the spool opens, allowing excess fluid to flow out of the system through the relief valve.

During the operation of the fire water supply system, the water flow direction of the main pipeline is from left to right, and all the way to control the water flow into the control room of the pilot valve. When the water pressure is lower than the set pressure relief value, the thrust of the pilot valve spring is greater than the water pressure, and the pilot valve disc is in a closed state. Another way of controlling water flow will generate a static pressure after entering the upper chamber of the main valve through the needle valve, and the pressure in the upper chamber is equal to the pressure in the flow channel. Because the upper plane of the main valve disc is larger than the lower plane, the pressure of the upper cavity on the disc is greater than the thrust of the water in the main channel to the disc, so that the main valve is in a closed state. If the pressure of the water flow in the main pipeline rises and exceeds the set pressure relief value, the pressure of the water flow entering the conduit control chamber through the control pipe increases, and the pressure of the water is greater than the spring thrust. At this time, the pilot valve is opened, and the upper chamber of the main valve begins to release pressure.

If the water flow pressure of the main pipeline continues to increase, the opening of the pilot valve will also increase accordingly, making the pressure difference between the upper and lower chambers of the main valve larger, the greater the opening of the main valve, and the faster the pressure relief of the system. Conversely, if the water flow pressure of the main pipeline decreases (such as when the number of fire hydrants used in the room increases or the number of nozzles opened increases), the pressure in the control room of the pilot valve will decrease accordingly, and the opening amount of the pilot valve will also decrease.

Features

1. Accurate and constant safe and stable pressure. Once overpressure, the pressure relief valve can be fully opened to release pressure in time.

2. The closing speed can be adjusted to eliminate pressure fluctuations.

3. Diaphragm drive mechanism minimizes operation hysteresis.

4. The pressure relief valve can be installed at any position, and can be maintained and inspected without changing the pressure setting value or removing it from the pipeline.

Application

The pressure relief valve is an important safety accessory on pressure vessels and other pressure equipment (such as water heaters, automobiles, etc.), and is generally installed on equipment or pipelines in closed systems to protect the safety of the system. Pressure relief valves are widely used in: steam boilers, liquefied petroleum gas, automobiles, liquefied petroleum gas, railway tank cars, oil production wells, high pressure bypass of steam power generation equipment, pressure pipelines, pressure vessels, etc.

In practical applications, pressure relief valves are usually used in conjunction with other control devices, such as safety valves, relief valves, and pressure control valves. Working together, these devices can effectively control the pressure in the hydraulic system and ensure the normal operation and safety of the system.

Through the above introduction, we have roughly understood the working principle of the pressure relief valve. From this we can see that the working principle of the pressure relief valve is actually not difficult. It stabilizes the pressure in the pipeline through the control of a series of physical and chemical factors. The parts of the pressure relief valve cooperate very skillfully to keep the system in normal condition, which largely guarantees the safety of the transported objects. After understanding these common senses, we can correctly deal with some problems in the plumbing at home.