Laser marking process of glass products

Sat, Aug 01 by ATO.com

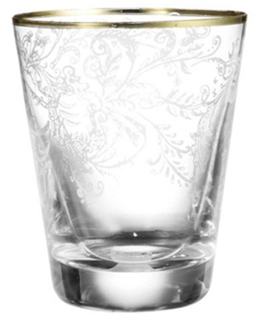

The glasses are widely used in the architecture, daily product, medical, chemical, home furnishing, electronic product, instrument, nuclear engineering and other fields. The glass is fragile. Therefore, it has a high technology to engrave on the surface of the glass products. The laser marking machine adopts non-contact processing, with short processing time and refined marking line. It can be used to make refined marking on the glass, such as any complicated character, image, pattern, trademark, LOGO, bar code, matrix code, batch number, signature and so on. All these can be completed with the laser marking machine. The following are the laser marking processes of glass products.

- Using laser emission for several times

One time of laser emission will be adopted to generate the marks with visible outlines. After several days, the laser will be expanded to the nearby area out of the original mark to form fragments. Then several times of emission will be used, so as to heat the adjacent area of the mark through heat conduction. As a result, these areas will form the stress gradient, thus reducing the possibility of secondary fracture. This approach is quite effective to mark on the soda-lime glass and borosilicate glass. The small-sized glass bottle which is used to contain the liquid medicament and the glass cups in our daily life are also using this approach to mark.

visible outlines. After several days, the laser will be expanded to the nearby area out of the original mark to form fragments. Then several times of emission will be used, so as to heat the adjacent area of the mark through heat conduction. As a result, these areas will form the stress gradient, thus reducing the possibility of secondary fracture. This approach is quite effective to mark on the soda-lime glass and borosilicate glass. The small-sized glass bottle which is used to contain the liquid medicament and the glass cups in our daily life are also using this approach to mark. - Discrete point forming annular crack

A series of annular cracks will be utilized to form characters, bar codes, squares, matrix code and other patterns. Usually, CO2 laser marking machine is employing this approach. Few cracks will be generated through setting the marking parameters on glass with the CO2 laser marking machine. The discrete points will appear, thus forming the annular cracks. Then the low-density annular cracks will be generated through heating and cooling circulation of the glass. When the glass is heated, expansion will be generated to extrude the surrounding materials. When the temperature rises to the temperature of the glass softening point, the glass will expand quickly and form bulgy dome in low-density material. Through CO2 laser marking machine, the manufacturer can mark beautify decorative patterns on the glass surface, so as to upgrade the grade of the glass.

When the glass is heated, expansion will be generated to extrude the surrounding materials. When the temperature rises to the temperature of the glass softening point, the glass will expand quickly and form bulgy dome in low-density material. Through CO2 laser marking machine, the manufacturer can mark beautify decorative patterns on the glass surface, so as to upgrade the grade of the glass. - Forming polygon surface crack

In the heating and cooling process, the surface of the acted glass will change. This approach is not visible immediately. The polygon crack will be generated along the laser marking area after exerting slight pressure. The polygon glass not only possesses the performance of the safety glass, but also has the ice-cracked and non-complete-transparent effect. Therefore, it is widely used in interior decoration, such as the partition wall and the background wall. In addition, it can also be used for the glass furniture. It is deeply favored by the consumers.