Laser markers are widely used in our daily life. Laser markers are also called laser marking machines, laser engraving machines, laser coding machines, laser inkjet printers, laser cutting plotters, etc. Different regions and different industries have other names. Because the materials of the processed products are different, the laser marking machines used are also different. There will be different laser marking machine equipment for various materials in various industries. Today, ATO will introduce three different types of laser markers for you.

Tag: laser marking

Laser markers use laser beams to mark permanent marks on the surface of various substances. The effect of marking is to expose the deep substance through the evaporation of the surface substance, to "engrave" traces through the chemical and physical changes of the surface substance caused by light energy, or to burn off part of the substance through light energy to show the pattern and text that needs to be etched. Laser marking machine is mainly divided into, CO2 laser marking machine, semiconductor laser marking machine, fiber laser marking machine, and YAG laser marking machine. At present, laser marking machine is mainly used on some occasions with more refined and higher precision. Now, let's take a look at the operating procedures and maintenance specifications of the laser marker.

Laser marking technology is a new type of marking technology without wear, contact, and pollution. The laser marker is a marking method that uses a high-energy-density laser beam to act on the target to cause physical or chemical changes on the target surface, thereby obtaining a visible pattern. It has the advantages of fast marking speed, clear marking pattern and writing, strong anti-counterfeiting function, and permanent wear-free marking pattern and writing. The laser marking machine is easy to operate and can achieve high-speed automatic operation with low production costs. Today, ATO will introduce the laser marking machine for you.

Fiber laser marker is a kind of laser marker, whose principle is to output laser through the laser, and then realize the marking function through the high-speed scanning galvanometer system. The fiber laser marker has higher photoelectric conversion rate, faster marking speed and smaller volume than the ordinary laser marker. What’s more, because of the characteristics of air cooling system and strong output beam quality stability, it is widely used in various industry. Here ATO shows how to buy best fiber laser marker.

When a fault occurs during the use of the laser marking machine, the problem should be solved in time, otherwise it will directly affect the workshop output. Actually, the maintenance of the laser marking machine is a little troublesome, but the working principle is very simple, so many problems can be solved by the operator without professional technicians. Here are several common problems and causes of laser marking machine.

Laser marking machine can provide the most professional solutions in the laser marking area of the whole automotive industry, from the car body, car frame, hub and tire, various hardware components, central control of the seat, steering wheel and instrument panel, glass, interior decoration, lighting, the assorted oils for cars, ornaments and so on.

When people are purchasing the laser equipment like the fiber laser marking machine, they will find that at present, there are many companies in the laser marking industry. Moreover, these big or small companies will quote different prices. Therefore, people may get confused in buying a laser marking machine. They don’t know where to start.

At present, different processing means and processing technologies constantly emerge. Although the traditional technical approach is also refining, it still can't satisfy the present processing demand. Laser drilling is the earliest practical laser processing technology. It is also one of the main application fields of the laser processing. The materials with high rigidity and melting point can't realize some of their technological requirements through the traditional processing means. However, it is totally not difficult to achieve through laser drilling.

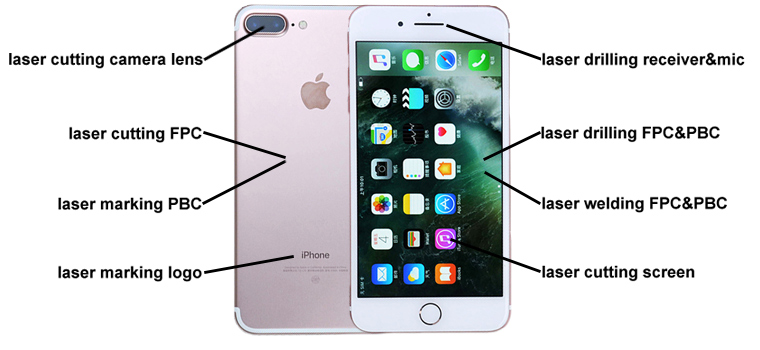

Except laser cutting, laser welding and laser marking technology, laser drilling is also one of the most important processing technologies in the mobile phone manufacturing. Because the laser can concentrate the energy in a very small area and it is controlled through the computer, it is very convenient to satisfy the processing requirement accurately.

In industrial manufacturing, laser is one of the most preferred marking technologies. Metal, plastic, ceramic and other materials can all be marked by the laser in wave length 1064nm (infrared ray), 532nm (green ray) and 355nm (ultraviolet ray). As a high-tech tool, the laser can be appropriate to mark numbers, texts, bar code and matrix code. For example in the figure below, laser marking on plastic bottle, adapter, container seal and ear tags.

The glasses are widely used in the architecture, daily product, medical, chemical, home furnishing, electronic product, instrument, nuclear engineering and other fields. The glass is fragile. Therefore, it has a high technology to engrave on the surface of the glass products. The laser marking machine adopts non-contact processing, with short processing time and refined marking line. It can be used to make refined marking on the glass, such as any complicated character, image, pattern, trademark, LOGO, bar code, matrix code, batch number, signature and so on. All these can be completed with the laser marking machine. The following are the laser marking processes of glass products.

The laser marking technology is one of the biggest application fields in laser processing. The laser marking can print out various characters, symbols and patterns. The character size can be ranged from the millimeter to micron dimension. This is of special significance to the refined processing of the product. As a modern precise processing mean, the laser marking technology has significant advantages compared with the traditional means of corrosion, electrosparking, mechanical carving, and printing processing.

At present, most electronic products, such as the main board of the mobile phone, computer and other key elements have identifications of traceable information. At the present stage, it is commonly adopted the ink label paper to stick on the product. However, such a mean has many problems, big amount of consumables, high pollution, high labor cost, the marks are easy to be eliminated and so on. Aimed at such condition, replacing the label paper by the laser marking code has become a tendency of the industry. With the automatic PCB laser marking machine, bar code, two-dimension code and character, pattern and other information can be marked on the printing circuit board and the relevant components.

Compared with the surface processing technology of the traditional metal nameplate, the appearance of the fiber laser marking machine succeeds in solving a series of difficult problems. Its characteristics lie in the high marking precision, fast speed and stable performance. Printing ink and other mediums are not required to cover the metal surface. Marks will be made on the surface of the nameplate directly with the laser. In addition, it is controlled through computer. It has easy operation and can print various kinds of complicated patters, characters, QR codes and other contents.

The aesthetic appreciation is the nature of every woman. Jewelry is an indispensable decoration of females. In purchasing the jewelry , the texture, color, appearance, workmanship and the peculiarity are elements must be considered in purchasing. Since most of the jewelry is made of gold, silver, Pt, diamond or other expensive raw materials, the requirements to the workmanship are also very high. As an advanced processing equipment, the fiber laser marking machine has become the first choice of numerous jewelry processing manufacturers because of its exclusive advantage.

, the texture, color, appearance, workmanship and the peculiarity are elements must be considered in purchasing. Since most of the jewelry is made of gold, silver, Pt, diamond or other expensive raw materials, the requirements to the workmanship are also very high. As an advanced processing equipment, the fiber laser marking machine has become the first choice of numerous jewelry processing manufacturers because of its exclusive advantage.

Stainless steel is a kind of modern general engineering material. It can be used in various industries. From the daily consumer products to the kitchen wares, from manufacturing the surgical operation device to the roof, stainless steel is always the best choice. There are over 150 types of stainless steels which can be purchased from the market. Their surface smoothness is also in great varieties. When the fiber laser marking technology is used on various stainless steel materials, there will be amazing effect. Many products or components made of stainless steel require marks of certain forms. No matter these marks are the manufacturing date or the simple alphanumeric code indicating the component number, or even the more complicated bar code or data bar code, ATO fiber laser marking machine can make marks without exception. The fiber laser marking machine can mark the typefaces in single lines, in hollow or solid. Some marks are rather complicated, such as the functional marks like the scales on the tools or instruments. Furthermore, the fiber laser marking machine can still engrave more complicated decorative patterns.

There are five matters need attention in choosing a laser marking machine.

I. The selection of the breadth size

II. Spindle motor of the laser marking machine

III. The selection of controlling means and speed

IV. Guide rail

V. Precision

Laser marking machine can mark the identifications well through the laser. Instead of attaching the identifications on the surface of the work pieces as the ink printing does, the laser marking machine will guarantee the durability of the marking effect. The identifications will also not disappear because of being touched with fingers for a long time, which plays an extremely important effect for us to operate the low-voltage apparatus correctly. Furthermore, the laser marking machine operates with no consumables, therefore, it reduces the marking cost, protects the environment and has the exquisite marking effect. All these are a promotion of the original ink printing.

The application area of the IC Card has covered many industries, such as the telecom, social security, bank, tax administration, public transportation, expressway card, gas filling card and so on. As the application scale of the IC Card enlarges, the packaging, printing and identifying business of the card have become the industrialization production. As the development of the IC Card industry and the improving card fabricating requirement, the printing mean of the card has also changed from the ink printing, heat transfer printing into laser printing.

The laser system will be able to choose a certain thin layer to line in the soft package. Such a behavior will be able to realize the perfect tearable effect and maintain the completeness of the thin layer, so that the outer layer will be kept perfect and not be damaged. As a result, we can prevent the products in the package from having problems of keeping in light and moisture.

- 1

- 2