Laser marking machine for food packaging industry

In the consumer goods industry, package has been an important aspect with particular concentration. In particularly, the food security is especially the top priority in food package.

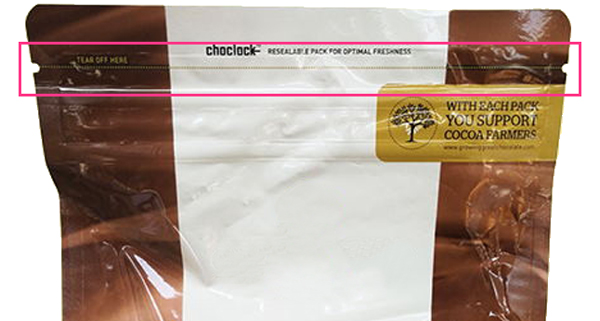

As to the most frequently-used sealing-type package, there are usually some problems, sometimes even making some small injuries. For example, when people are opening the package of the peanut or salad dressing, the contents in the package are easy to flow out. Such a condition is most easily to happen for some packages with tight sealing or improper design. Furthermore, the tearing line may be forgotten to make because of the negligence. Or sometimes, the tearing line made by mechanical approach should be tore with great strength. Therefore, the strength is hard to control in opening some food packages.

The present advanced laser marking technology has provided us with scheme of solving the problems. The laser system will be able to choose a certain thin layer to line in the soft package. Such a behavior will be able to realize the perfect tearable effect and maintain the completeness of the thin layer, so that the outer layer will be kept perfect and not be damaged. As a result, we can prevent the products in the package from having problems of keeping in light and moisture.

In addition, the present advanced laser marking machine system can make line according to the free combination mean randomly. For example, many snacks adopt the package type, which is the design style to mark line as the outline of the printing pattern on the package. This marking approach is exactly the advantage of the laser marking system.

Moreover, when the packaging bag has to make holes, the laser system can make holes to the package for “ventilation and preservation”. This is the most advanced technology in the world at present. Through making holes, the refreshing time of the commodities in the package will be prolonged. Furthermore, making holes is also catering to the pressure to the food package after being heated in the microwave oven.

Now, the laser drilling line can realize the effect of tearing the whole package along the hidden line. Different from the circular knife, punching machine or any other machine tool, there is no need to have direct contact for laser operation. Only the extremely small abrasion and cutting will be able to provide the best processing mean.

Application of laser scribing technology

Laser scribing is a kind of technology utilizing laser to realize the effect of "easy to tear" on the multi-layer composite package material. Compared with the traditional tools, it is a more advanced and more flexible technology. The laser scribing technology concentrates the laser energy on the thin film needs to be scribed, instead of damaging the whole film. It is because the composite films, like PET, PP or PE have different characteristics of absorbing and launching carbon dioxide laser wavelength. Therefore, when the film absorbs the laser energy and disappears, other film layers will keep a 100% of not being influenced.

On the other hand, the aluminum foil layer or other films plated with metal layer will become the shield of preventing the laser from going to other material layers. Therefore, the characteristics of these materials can enable the laser technology to have precisely positioning and scribing on the package material. Meanwhile, the tearing line is visible to human eyes. Therefore, tearing the package has become an easy thing for the consumers. Moreover, it’s worth noting that the laser scribing technology is a non-contact process with no erosion to the food package. Therefore, it can make sure that the products in the package will not be damaged in the packing process, so as to ensure the stability and reliability of the commodity.

Application of the laser drilling technology

As everyone knows, the quality and storage life of the perishable food depends on the air circulation and the moisture balance in the product package. Therefore, in order to ensure that the package can have enough holes, the employment of the laser technology to make holes has become the first choice for the perishable food. The processing equipment can adopt the carbon dioxide laser in high impulse to make holes to each film layer of the package material. Through the special technology, every hole possesses the required fusion, thus preventing from enlarging the holes effectively and avoiding destroying the package completeness. Meanwhile, it will have good ventilation and moisturizing effect.

The present advanced laser equipment can provide various solutions according to the output and technological requirement of the product. The punching direction can be controlled by the optical splitter, equipped with several focusing heads. The polygon prism can be utilized to distribute the light velocity on several focusing heads to achieve high-speed rolling. At present, the best pore diameter of the climate managing package of the soft package is between 60 and 300 micrometer. The arrangement of the small holes can be changed according to the practical requirements. In addition, it can be conducted synchronously as printing.

The laser drilling technology is also applicable to the packages with pressure change, such as the food package requires for microwave heating. As to some hard package materials, such as the PE/PE composite material, the laser drilling technology can punch line with 5-50 holes in every 1 cm. It can fully have the tearable effect of along the hidden line.

The merits of using the laser drilling and laser scribing technology in food package

- Only scribe the selected film layer, other film layers will not be affected.

- Can choose the scribing pattern freely.

- Have little loss and high reliability in the manufacturing process.

- Have precise control to the size and quantity of the hole.

- Can punch slim holes, with edges uneasily to break.

- Can fabricate the tearable hidden line with high-density small holes.

As the consumption ability of human beings increases, people put forward higher requirements to the quality of the consumption products. The humanized food package is easier for the customers to accept. It will also play a certain role in promoting the marketing condition of the products.

Buying an ATO laser marking machine now, handheld fiber laser marking machine, 20w fiber laser marking machine...