Laser drilling technology for aero turbine engine vane

At present, different processing means and processing technologies constantly emerge. Although the traditional technical approach is also refining, it still can't satisfy the present processing demand. Laser drilling is the earliest practical laser processing technology. It is also one of the main application fields of the laser processing. The materials with high rigidity and melting point can't realize some of their technological requirements through the traditional processing means. However, it is totally not difficult to achieve through laser drilling.

The laser drilling machine is to concentrate the laser beam highly in both space and time. Through the focusing lens, the diameter of the light spot can be minimized to the micron level, so as to obtain the laser power density of 105-1015W/cm2. Such a high power density can conduct laser drilling on almost every material. In addition, compared with other approaches, such as the mechanical drill, electro spark processing and other conventional drilling methods, it has the significant advantages of processing small holes on the inclined surfaces of the materials which are difficult to be processed.

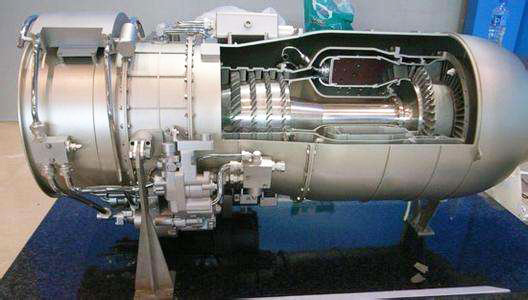

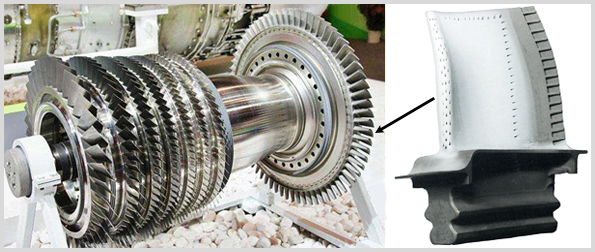

The present aero turbine engine has a relatively high working temperature to its engine, which can reach 1360℃. Numerous materials can reach the melting point under this temperature. Therefore, the manufacturing of the aero turbine engine vane requires very complicated method for cooling. At this moment, it is required to process tiny holes on the vane to ensure the circulation of cold air, thus preventing from damaging the vane under excessive temperature. In addition, it is also required to make sure that the blade can have stable and high-speed revolving under the strong airflow pressure. Therefore, the appropriate positions have to be found in drilling on one hand. The performance of the blade should not be weakened on the other hand. The precision requirement in this process is extremely high. If the traditional technological approach is adopted, it will have complicated process and the precision will not be reached. Therefore, the laser drilling technology is necessary at this moment.

The laser drilling for the aero turbine engine vane is to inject a laser beam into the water column with thickness similar to the hair. The water column will act as the optical fiber to guide the laser to the surface of the aero turbine engine vane. This approach will not only be beneficial for reducing the temperature of the material, but also help to remove the crisp pieces generated in processing. It not only improves the performance of the aero turbine engine greatly, but also provides more innovation for the design of the present aero turbine engine. It is believed that the application of laser technology in the aviation field will be extended with the continuous improving laser technology and the increasing matured relevant technology in the future. The present fiber laser marking machine, laser welding machine, laser cutting machine and so on are widely used in the aviation field. Their distinct characteristics are adding more vitality to the present aviation field, so as to promote the development of the aviation industry vigorously.