Laser marking technology on electronic products

Wed, Jan 28 by ATO.com

The laser marking technology is one of the biggest application fields in laser processing. The laser marking can print out various characters, symbols and patterns. The character size can be ranged from the millimeter to micron dimension. This is of special significance to the refined processing of the product. As a modern precise processing mean, the laser marking technology has significant advantages compared with the traditional means of corrosion, electrosparking, mechanical carving, and printing processing. In the following paragraph, it is going to introduce some new applications and technologies of laser refined carving on the surface treatment of electronic products.

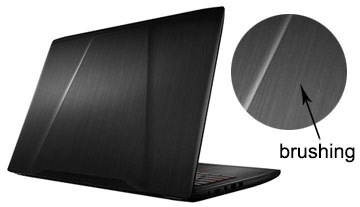

- Laser brushing on laptop shell

The present market growth of the laptop is very fast and the competition is also intense. New processing technologies also keep on emerging, in which the laser brushing of the laptop shell is the representative of the latest processing technology.

Through the laser brushing technology, the rigidity of the laptop shell can be ensured from one hand, the heat can also be eliminated on the other hand. It has fine, beautiful and fashion processing, combining the humanization and business entertainment. In addition, it has more texture and dignity.

The laser marking machine with large format is adopted to draw wires and carve patterns to the laptop shell at a speed of 1,600mm/s. The maximum speed can reach 10,000mm/s. The complicated patterns engraving and filling for the panel of a laptop in 14 inches will be finished in seven minutes. It can carve patterns on the aluminum shell, magnalium shell and stainless steel housing. The patterns are beautiful, with neat edges. It is the best technology to replace the silk printing and knife carving. Afterwards, electrosilvering will be made after engraving to release the texture. - Oxygen breaking on the alloy surface of the CO2 galvanometer carving machine

Dynamic gathering CO2 galvanometer carving machine to break oxygen on the surface of the magnesium alloy, oxygen breaking of the laptop heat sink strip, with high efficiency and catch no fire. The carving precision is high and the filling mean is proper and speedy. - Laser marker for keyboard photopermeability and plastic components

The large-format marking of the entire laptop keyboard exempts repeatedly assembling and guarantees the marking efficiency. The marking time of the entire page can be completed in about 15s.

- Marking of the mobile phone keypad

- UV laser marking

Different from the IR processing, UV micro programming is essentially not heat treatment. In addition, it is easier for most materials to absorb UV light than the IR light. The high-energy UV photons will damage the molecular bonds of many non-metal materials. The components processed by this "cold" light etching processing technology can have smooth edge and the lowest carbonization. In addition, the intrinsic characters of the UV short wavelength have a certain superiority in the micro programming of the metal and polymeric machine. It can be concentrated on the spots of the submicron quantity level. Therefore, it can be used to process the tiny components. Even though under the level of not high pulse energy, a very high energy density can be obtained, so as to process the material effectively.

The three advantages of the UV laser to engrave the materials, compared with the IR and green ray laser.

a. More types of materials will have more absorption to the UV laser.

b. The UV photon has stronger energy, for example, the UV laser of 1W is equivalent to the energy of the IR laser in 3W.

c. Can be concentrated to smaller light spots.

355 nm UV laser has short wave length. Its concentrated light spot is much smaller. It belongs to the cold processing, with less heat influence. Therefore, it is particularly suitable for marking on the surfaces of the glass, high polymer material, micropore processing (pore diameter d≤10μm) and flexible PCB plate, LCD, TFT marking, scribing cutting and so on. - Laser colorful marking

The laser colorful marking machine adopts the latest optical technology and the special water temperature controlling system, so as to make the laser has a stronger power and a more stable light beam. It has advantages in colorful and transmitting pressing keys. The colorful label is suitable for marking on the surfaces of the various metals, dies, plastic cements, PVC ceramics and so on. It has improved the product quality and it is an innovation of the traditional carving technology. - Laser deep marking

The laser deep marking has fewer applications at present. It is mainly used on blacking and deepening the bearings and crafts. Compared with the traditional mechanical engraving, the laser deep marking has more exquisite effect, stronger stereoscopic impression and faster speed. It is a new surface processing technology with great market potential.

20w fiber laser marking machine is employed to conduct deep marking to the copper aluminium alloy. It is suitable for marking, deepening and blacking almost all metals, ceramics, plastic cements, such as the bearings.