Planetary Speed Reducer Installation Guide

The correct installation, use and maintenance of the planetary speed reducer & gearbox are important parts of guaranteeing the normal operation of the machine and equipment. How to install the motor to the planetary gearbox properly? Here are some tips for your reference.

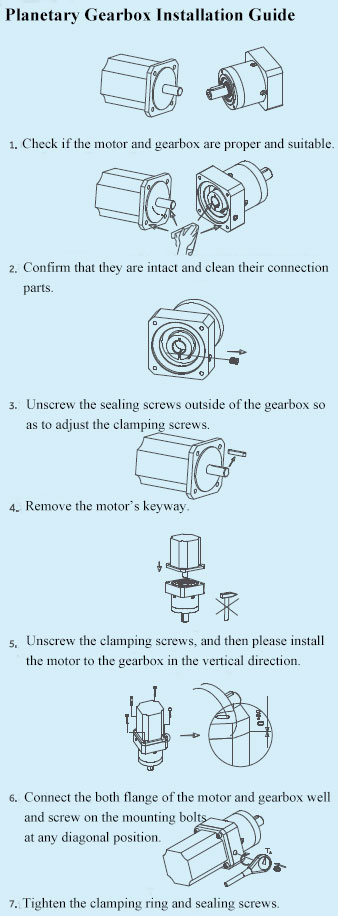

1. Before installation, please check whether both the motor and planetary gearbox are intact.  In addition, please strictly check if the sizes of all the connecting parts between the motor and planetary gearbox are matched. Here the sizes refer to the dimensions and fit tolerance of the motor’s positioning boss, input shaft and gearbox’s groove, etc.

In addition, please strictly check if the sizes of all the connecting parts between the motor and planetary gearbox are matched. Here the sizes refer to the dimensions and fit tolerance of the motor’s positioning boss, input shaft and gearbox’s groove, etc.

Besides, please wipe the rust-proof oil or zinc sodium water on the motor’s input shaft, positioning boss and the gearbox’s connection parts, with the purpose to guarantee the tightness of the connection and the flexibility of the operation and prevent the unnecessary wear.

2. Unscrew the screws on the dust hole outer of the gearbox flange and adjust the clamping ring to align the side hole with dust hole. Then insert the hexagon socket to tighten it. After that, remove the shaft key of the motor.

3. Please connect the motor and planetary speed reducer gearbox naturally. Then connection must keep the consistent concentricity of the gearbox’s output shaft and the motor’s input shaft and both outside flanges are in parallel. If the concentricity is inconsistent, the motor shaft will be broken or the speed reducer’s gears will wear off.

4. Before connecting the motor and reducer, the motor shaft keyway should be perpendicular to the clamping bolt. During the installation, it is forbidden to hit with a hammer, thus preventing the bearing or gear from being damaged due to too large axial force and radial force. Please be sure to tighten the mounting bolts before tightening the clamping bolts. In order to ensure uniform force, firstly screw on the mounting bolts at any diagonal position, but do not tighten them, then screw on the mounting bolts at the other two diagonal positions and finally tighten the four mounting bolts one by one. Finally, tighten the clamping bolts. All clamping bolts need to be fixed and inspected with the torque wrench according to the indicated fixed torque data.

5. The proper mounting between the planetary speed reducer and machinery is similar to the correct installation between the reducer and driving motor. The key is to ensure that the output shaft of the speed reducer or gearbox is concentric with the driven shaft.