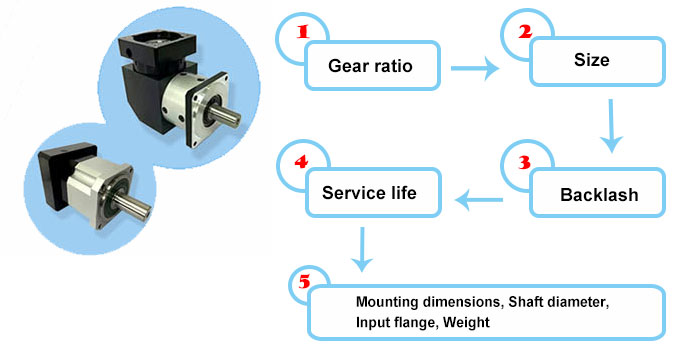

Planetary Speed Reducer Gearbox Selection Guide

In the family of gearboxes, the planetary speed reducer or gearbox is widely used in transmission systems such as servo motors, stepper motors and DC motors due to its small size, high efficiency, wide deceleration range and high precision. In the premise of ensuring the precision transmission, it is mainly used to reduce the speed, increase torque and reduce the inertia ratio of the loads or motors. Thus, how to choose a right planetary speed reducer or gearbox to fit a motor?

1. Gear ratio

When selecting a planetary speed reducer/gearbox, the first thing is to confirm the gear ratio. If there is no gear ratio as you required, it is recommended to choose the similar one or customize a planetary gearbox from ATO.com.

After confirming the gear ratio, please multiply the rated torque of your selected servo motor by the ratio, and then you get a value which is smaller than the nominal output torque of the gearbox provided in the catalog in principle. Meanwhile, the overload capacity to drive motor and the actual need of the maximum working torque should also be taken into consideration. The required maximum working torque is normally twice smaller than the nominal output torque.

2. Size

The above conditions are satisfied, and then please choose a planetary gearbox in smaller size. Smaller size of planetary speed reducer gearbox relatively costs less. If there is not enough space to connect the motor and planetary gearbox in straight line, right-angle planetary speed reducer gearbox is also an option that can turn the torque 90 degrees.

3. Precision (Backlash)

The smaller the backlash is, the higher the precision is and the higher the cost is. So just choose the planetary speed reducer whose backlash can meet the requirement of the precision.

4. Service life

The average service life and the radial and axial force should also be considered. The planetary speed reducer with large radial and axial force has higher reliability in the installation and operation. Usually, the average service life is much longer than the life of the equipped servo motor.

5. Others

After meeting the above requirements, select a planetary speed reducer to fit your motor in terms of the mounting dimensions, shaft diameter and input flange according to the product catalog. Then take the weight of the motor into account. The planetary speed reducer is allowed to match the motor which is less than a certain amount of weight. If the motor is too heavy, it will damage the output flange of the planetary gearbox in long operation.