Variable Frequency Drive Relay Output Setup

Variable frequency drives (VFDs) have most commonly been used in water treatment plants, where they're used to regulate water flow. But in recent years, they've grown in popularity throughout many areas of the industry.

Advantages of VFD:

- Process Optimization. VFDs make automation or industrial process operate more smoothly. With speed control based on flow rate, AC motors operate more efficiently and effectively. By incorporating PLC programming, VFDs can also run via automation, eliminating the need for manual operation. Control programming employee working at his computer to program PLC for an industrial applicationThrough the use of basic communication protocols, PLCs monitor and control motor speeds using the VFD. This leads to a more efficient process. Plus, it effectively cuts out hammering effects due to pipe flow. Overall, VFDs can make your facility's operations more efficient and sophisticated while giving operators better control of their process.

- Increased Motor Life. As it turns out, improving the efficiency of motor-based systems can also be great for the motor. By enabling an AC motor to run at speeds appropriate to the flow rate, VFDs decrease strain and wear to the motor during operation. VFDs make it possible for AC motors to ease into startup, rather than only switching between off and full speed. With a gradual startup, motors experience less strain. Both the gradual startup and the ability to adjust speed based on flow rate decrease stress to the motor.

- Energy Saving. VFDs adjust to allow a motor to run at slower speeds when needed, which reduces overall energy consumption. With this alone, a variable frequency drive tends to pay for itself in under two years. Energy companies are aware of the energy savings VFDs bring to facilities and have started offering their own incentives.

- Time Saving. Any process inefficiency within a production facility equals wasted time. And wasted time is the same as dollars left on the table. By easing motor wear, VFDs extend motor life and reduce the need for repairs. And by automating what could otherwise be a manual process component, VFDs save on labor costs as well.

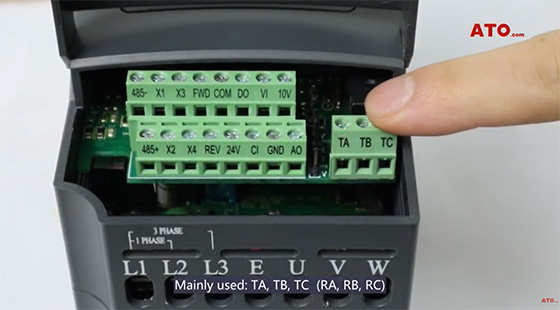

In the following, I will show VFD relay output settings, mainly used: TA, TB, TC (RA, RB, RC)

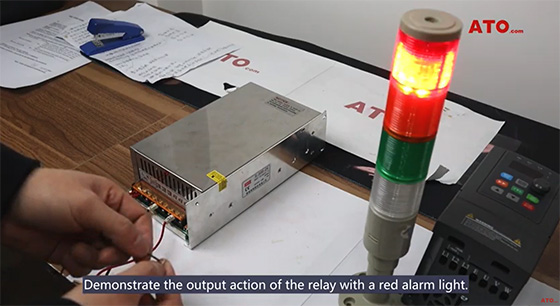

Demonstrate the output action of the relay with a red alarm light. And then connect the signal line of the alarm light to the normally open contacts TA and TB. (TA and TC are normally closed contacts)

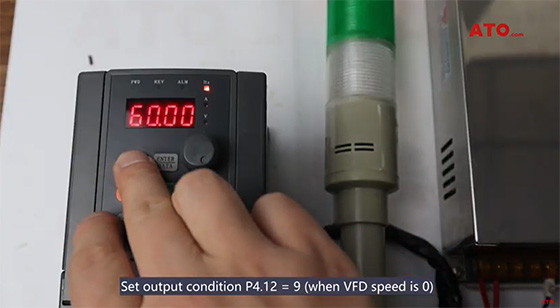

Set output condition P4.12=9 (when VFD speed is 0). Relay is normal.

Start VFD. Adjust the speed setting to 0. At this time, the warning light is activated. Read it again.

If you want to learn more about variable frequency drive, please click this video or contact us.