What is DC-DC Converter?

The Purpose of DC-DC Converter

In modern electronic devices, different circuit modules often require different voltages to operate properly. For example, a microprocessor may require a stable 1.2V core voltage, a touchscreen may require a 3.3V drive voltage, and a motor may require 12V or even higher. However, our power supplies—whether batteries, adapters, or solar panels—typically only provide a fixed voltage (such as a 5V USB port or a 12V battery).

So, how can we obtain these diverse, stable, and precise voltages from a single power source? The answer is the DC-DC converter.

Like an efficient "voltage translator" or "power transformer", its core purpose is to efficiently convert one direct current (DC) voltage to another. In other words, a DC-DC converter power supply can "tailor" the precise voltage required by each circuit module, ensuring stable and efficient operation of the entire system.

Working Principle of DC-DC Converters

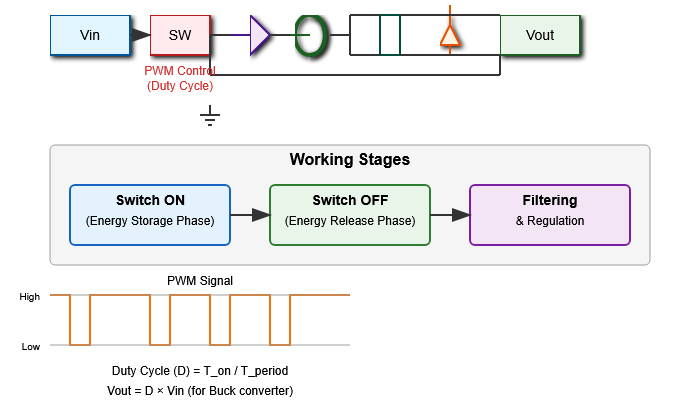

Most modern DC-DC converters use switching-mode technology, which relies on fast switching, inductor energy storage, and capacitor filtering. The basic operating principle can be summarized in three steps:

- Switch On (Storage Phase): A high-speed switch (such as a MOSFET) is closed, allowing current to flow from the input through the inductor and load. Energy is stored in the inductor (in the form of a magnetic field) while simultaneously charging the output capacitor.

- Switch Off (Discharge Phase): The switch is turned off. Because the inductor resists the change in current, it generates a reverse electromotive force, reversing its polarity. At this point, the energy stored in the inductor is released through a diode (or another synchronous switch), continuing to power the load.

- Filtering and Regulation: The output capacitor acts as a "small reservoir," absorbing ripple and smoothing these pulsed currents, ultimately producing a smooth, pure DC output.

The DC-DC converter uses pulse width modulation (PWM) to adjust the duty cycle, thereby controlling the output energy and ultimately achieving precise regulation of the output voltage.

Three Types of DC-DC Converters

Based on the relationship between input and output voltages, DC-DC converters are categorized into three basic types:

Boost (step-up) DC-DC converters

A boost converter, also known as a step-up converter, performs the opposite function of a buck converter. It boosts a lower input DC voltage to a higher, regulated output DC voltage. Its output voltage is always higher than the input voltage (Vout > Vin).

It operates based on a high-speed switch (usually a MOSFET), an inductor, a diode, and an output capacitor. When the switch is closed, the input voltage charges the inductor, storing the energy in the form of a magnetic field. The diode is then cut off, and the load is powered by the output capacitor. When the switch is open, an induced electromotive force is generated in the inductor. Its polarity is added in series with the input voltage, forcing the voltage to rise, supplying power to the load through the diode while charging the output capacitor. The magnitude of the voltage boost is determined by controlling the switch duty cycle. A higher duty cycle results in a higher output voltage.

Typical applications include LED driver circuits, such as in flashlights or LED backlights, where the voltage of a single or two batteries (1.8V-3V) is boosted to a high voltage (above 10V) sufficient to drive multiple LEDs in series. In battery-powered devices, when the battery voltage drops as it discharges, the boost converter can maintain a constant output voltage to ensure normal operation of the device. Boost converters are also used in solar systems to boost the voltage generated by photovoltaic panels.

Buck (step-down) DC-DC converters

A buck converter, also known as a step-down converter, converts a higher input DC voltage to a lower, regulated output DC voltage. Its output voltage is always lower than the input voltage (Vout < Vin).

The circuit also consists of a switch, an inductor, a diode, and a capacitor. When the switch is closed, the input voltage is connected to the inductor, and current flows through the inductor and the load, storing energy in the inductor's magnetic field. When the switch is open, the inductor generates a reverse electromotive force to maintain current continuity, reversing its polarity. This stored energy is released through the freewheeling diode, continuing to power the load. The average output voltage can be adjusted by controlling the ratio of the switch's on and off time (duty cycle) through pulse-width modulation (PWM). A larger duty cycle results in a higher output voltage.

Buck DC-DC converters are widely used in applications requiring lower operating voltages. For example, on computer motherboards and graphics cards, 12V power is converted into a core voltage of around 1V required by the CPU or GPU. In automotive electronic equipment, 12V or 24V battery voltage is converted into 5V or 3.3V to power mobile phones and entertainment systems. In addition, it is also commonly found in the power management modules of various portable devices.

Boost-Buck (step-up/down) DC-DC converters

A boost-buck converter, also known as a step-up/down DC-DC converter, is a highly flexible power converter capable of automatically stepping up or down the voltage in response to input voltage fluctuations. Its output voltage can be higher, lower, or equal to the input voltage, making it particularly suitable for applications with widely fluctuating input voltages.

This circuit topology combines the features of both boost and buck converters. When the input voltage is higher than the desired output voltage, it operates in buck mode; when the input voltage is lower, it switches to boost mode. Complex control circuitry regulates the switching timing and duty cycle, ensuring a stable, preset output voltage regardless of input fluctuations.

The most typical application is single-cell lithium-ion battery-powered devices. Lithium batteries typically operate between 3.0V and 4.2V, while many electronic systems (such as microcontrollers and sensors) require a stable 3.3V voltage. The boost-buck converter steps down the voltage when the battery is fully charged (4.2V > 3.3V) and steps up the voltage when the battery is nearly depleted (3.0V < 3.3V). This consistently provides a stable 3.3V output, significantly extending the device's useful life. It is also widely used in battery management systems and other applications where the input source is unstable.

Advantages of DC-DC Converters

Compared to traditional, inefficient linear regulators (LDOs), switching DC-DC converters offer the following significant advantages:

- High efficiency: This is their primary advantage. Switching between the on (low resistance) and off (no current) states consumes very little power, typically achieving efficiencies exceeding 90%. This means less energy is wasted as heat and longer device life.

- Flexibility: They can easily step up, step down, and even invert voltage, meeting the diverse voltage requirements of complex systems.

- High current support: They can efficiently handle a wide range of power, from milliwatts to kilowatts, for a wide range of applications.

- Excellent thermal management: Due to their high efficiency, they generate far less heat than linear regulators, reducing the design complexity and cost of system cooling.

In short, DC-DC converters are the unsung heroes and energy hubs of modern electronic devices. They work silently in every corner of the circuit board, efficiently and accurately "distributing" electrical energy into various required forms, ensuring the stable and efficient operation of all complex electronic devices, from smartphones to data centers, from electric vehicles to renewable energy systems. What kind of DC-DC converter does your project need? Whether it's boost, buck, or boost-buck, ATO one-stop automation online shop provides you with a complete selection of efficient, stable, and cost-effective options.