6 Causes of Solid State Relays Failures and Solutions

Solid state relays (SSR) utilize semiconductor devices for switching control, eliminating mechanical wear and contact oxidation issues inherent in electromechanical relays. However, in practical applications, latent factors such as heat accumulation, long-term aging, and environmental wear can still cause SSR performance degradation or sudden failures, compromising circuit system stability. This blog dissects the 6 most common causes of SSR failures and provides corresponding solutions based on proper installation and maintenance practices. It offers clear guidance for practitioners to mitigate risks and extend equipment lifespan.

6 Common Causes of SSR Failure:

- Overheating

- Voltage Spikes and Surges

- Overloading and Overcurrent

- Improper wiring

- Contamination

- Age and Wear

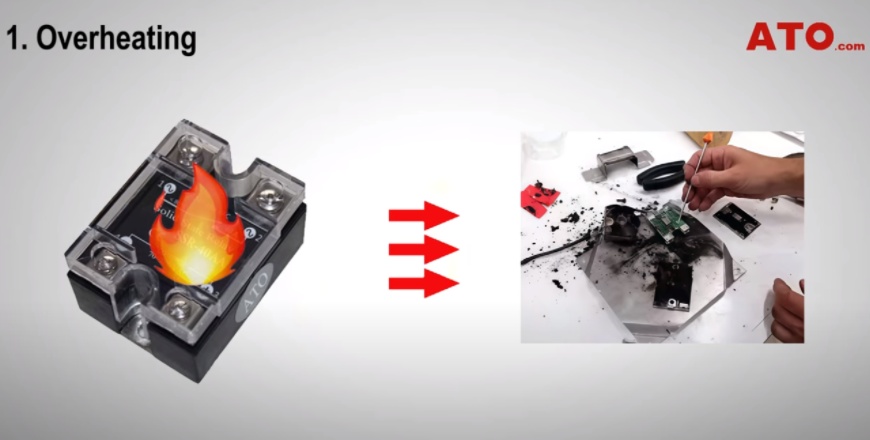

Overheating

Overheating is a leading cause of solid state relay failures. Inadequate thermal management causes excessive internal temperature buildup, which accelerates semiconductor degradation and significantly shortens the SSR’s service life.

Solution: To combat overheating, a proper heat sink and ensuring adequate ventilation around the SSR can help alleviate thermal issues and maximize its lifespan.

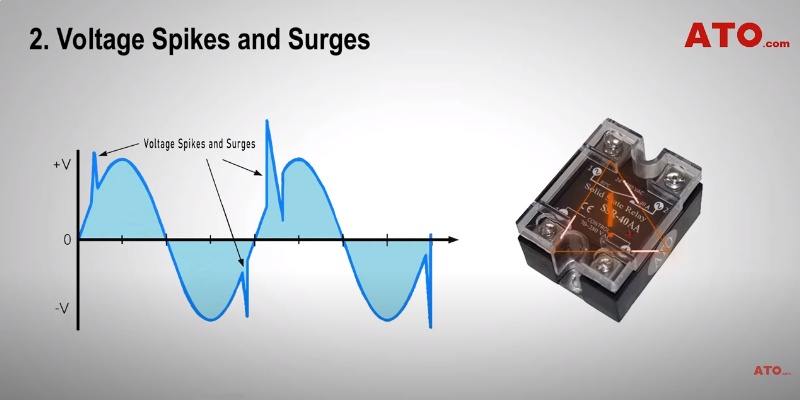

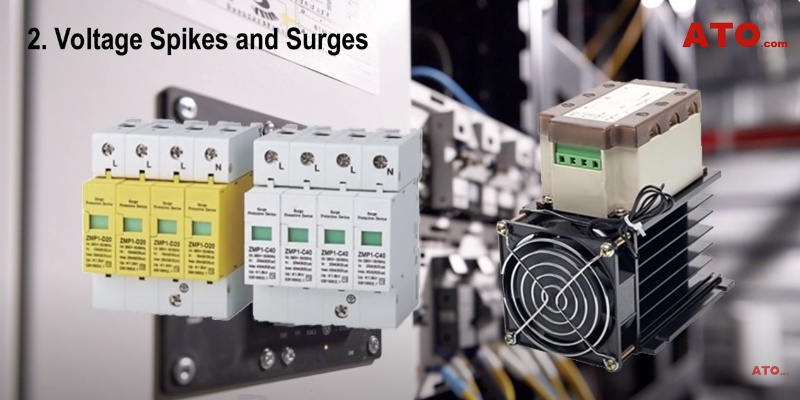

Voltage Spikes and Surges

Voltage spikes and inrush currents from inductive and capacitive loads can suddenly damage the input and output components of solid state relays, particularly during power fluctuations. This not only impairs SSR functionality but also accelerates its aging process.

Solution: To mitigate external load impacts, install surge protectors and voltage regulators to protect solid state relays from sudden voltage fluctuations.

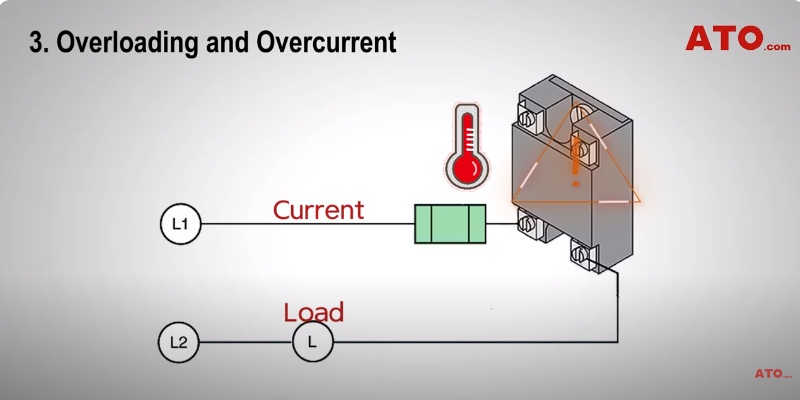

Overloading and Overcurrent

- Excessive load/current: When the load or current exceeds the relay’s rated capacity, it triggers excessive heat buildup. This heat induces thermal stress on internal components, ultimately resulting in SSR failure.

- Overvoltage: Exposing the SSR to voltage levels beyond its maximum rating can cause irreversible breakdown of its semiconductor devices, directly leading to complete loss of the relay’s functionality.

Solution:

Solution:

- To prevent overload and overcurrent, you need to carefully calculate the load requirements and properly size the SSR for the intended load. And you can enhance safety by implementing appropriate current-limiting measures, such as fuses or circuit breakers.

- To protect the SSR from overvoltage, you can employ surge protectors or transient voltage suppressors.

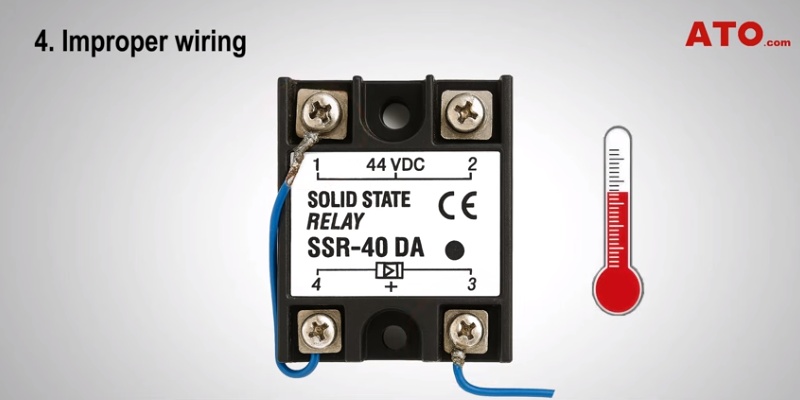

Improper wiring

Using SSR with loose screws, poor soldering, or improper wiring can lead to excessive heating during current flow and may eventually damage the relay components.

Solution: To avoid this, ensure correct soldering and wiring. Additionally, keep signal and power cables separate and consider using shielded wires to reduce electrical noise and interference.

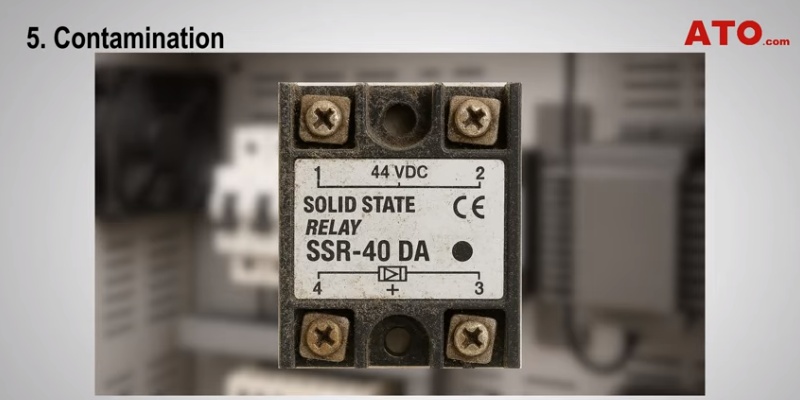

Contamination

The operating environment is also critical for the reliable performance of solid-state relays. Exposure to contaminants such as dust, dirt, or moisture can penetrate the relays, leading to short circuits and functional malfunctions.

Solutions: Periodically clean and check the relay housings, and employ protective covers to guard the relays against contaminants.

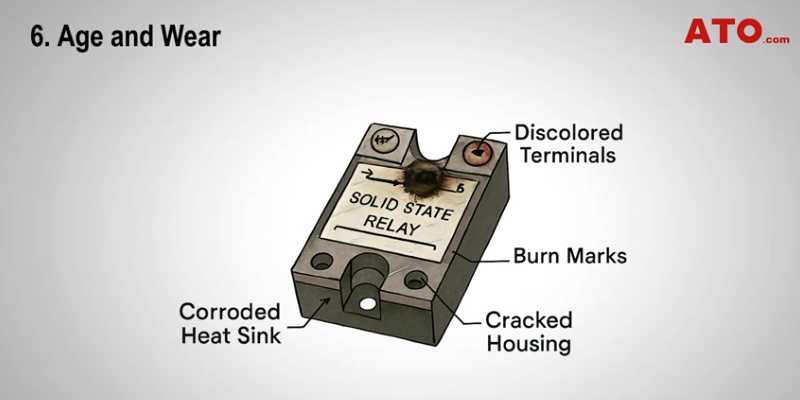

Age and Wear

Solid-state relays, like other electronic components, degrade over time, which raises the risk of failure.

Solutions: Regularly inspecting SSR for signs of wear or damage can help detect potential problems early. Alternatively, replacing aging relays with new ones ensures continued system reliability and optimal performance.

Conclusion

By understanding the causes of SSR failures and applying preventive maintenance, proper installation, and quality components, you can ensure reliable operation, strong performance, and long service life of your electrical systems.

If you have any questions, you can watch the video below. For more guides and troubleshooting tips, visit ATO.com.