AC Motors vs DC Motors

Electric motors are the driving force behind modern industry and everyday technology, converting electrical energy into mechanical motion. From household appliances to large-scale industrial machinery, motors play a vital role in countless applications.

Among the many motor types available today, DC motors and AC motors are the most widely used. Although both serve the same fundamental purpose, they differ significantly in operating principles, structure, performance characteristics, and application suitability.This article offers a detailed comparison of DC and AC motors, explaining their operating principles, key differences, and the applications where each performs best.

Contents

- Introduction

- Key Differences

- Advantages and Limitations

- Applications

- How to Choose the Right Motor

- Conclusion

Introduction

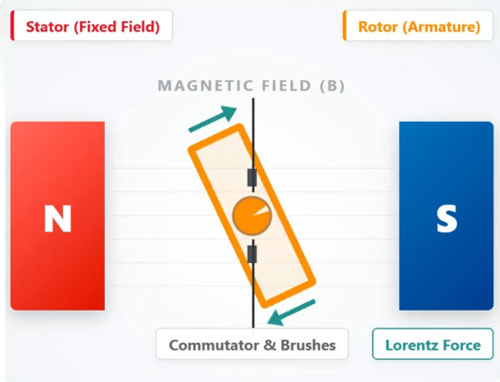

DC Motor

DC motors convert direct current electrical energy into mechanical power and operate based on the Lorentz force principle, whereby a current-carrying conductor placed in a magnetic field experiences a force. In a typical DC motor, the stator generates the magnetic field while the rotor (armature) carries current and rotates due to electromagnetic interaction. In brushed DC motors, commutators and brushes are used to periodically reverse the current direction in the armature windings, ensuring continuous and stable rotation.

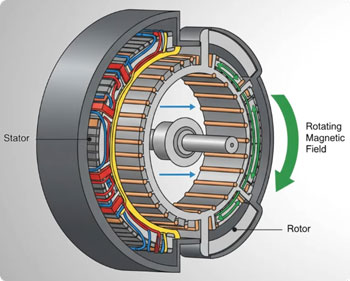

AC Motor

AC motors operate using alternating current, with induction motors being the most common type. Their operation is based on a rotating magnetic field generated by AC flowing through the stator windings, which induces a current in the rotor. The interaction between the induced rotor current and the rotating magnetic field produces torque, causing the rotor to rotate. AC motors are generally classified into single-phase and three-phase types, with three-phase AC motors being widely used in industrial applications due to their high efficiency, reliability, and suitability for continuous operation.

Key Differences

When it comes to selecting the right motor for your application, understanding the fundamental differences between DC and AC motors is crucial. These two motor types may serve the same purpose of converting electrical energy into mechanical motion, but they operate on distinct principles that influence their design, performance, and suitability for different tasks. In this section, we'll explore the key differences between DC and AC motors, including their power supply, construction, startup characteristics, speed control, maintenance needs, and emerging hybrids: BLDC & VFD AC helping you make an informed decision for your specific requirements.

1. Power Supply

The most fundamental difference between DC and AC motors lies in their power source. DC motors operate on direct current supplied by batteries, rectifiers, or DC generators, where the current flows in a single direction at a constant voltage.

In contrast, AC motors are powered by alternating current from power grids or AC generators, in which the current periodically reverses direction—typically 50–60 times per second. This distinction significantly affects motor design, performance characteristics, and speed control methods.

2. Construction and Design

DC motors, which consist of an armature, commutator, and brushes, generate high torque at zero speed, making them ideal for lifting and traction applications. The field windings create a stationary magnetic field, while the armature windings carry direct current supplied through the brushes and commutator. As current flows through the armature windings within the magnetic field, electromagnetic torque is produced, causing the armature to rotate. The commutator and brushes reverse the current direction in the armature, ensuring continuous rotation and stable motor operation. However, brush wear introduces maintenance requirements.

On the other hand, the structure of AC motors varies based on the type. AC motors, especially asynchronous (induction) ones, have a simpler, brushless design, primarily consisting of a stator and a rotor. The stator contains windings, while the rotor is either squirrel-cage or wound type. When powered with three-phase AC, the stator generates a rotating magnetic field. The relative motion between the rotor and this field induces an electromotive force (EMF) and current in the rotor. The interaction between the induced current and the magnetic field produces torque, causing the rotor to turn. In induction motors, the rotor speed is slightly lower than the synchronous speed of the rotating field (slip). Unlike asynchronous motors, synchronous motors include an excitation system that allows the rotor to rotate in sync with the stator’s magnetic field.

3. Startup Characteristics

DC motors are compact, offer high starting torque, and provide easy, precise speed control, making them ideal for applications requiring rapid acceleration or frequent starts. However, their less impressive starting torque in certain situations requires starters or VFDs to overcome high inertia. In comparison, AC motors, especially induction motors, have lower starting torque due to inductive effects. Yet, modern control techniques like soft starters and VFDs can enhance their startup performance, offering smoother acceleration and better control.

4. Speed Control

DC motors offer excellent speed control over a wide operating range. By adjusting the armature voltage or the field current, smooth and precise speed regulation can be achieved using relatively simple control circuits. This makes DC motors particularly well suited for applications that require frequent speed changes or accurate speed control.

AC motors, by contrast, typically require additional equipment for speed control. The speed of induction motors is mainly regulated by adjusting the supply frequency, most commonly through the use of variable frequency drives (VFDs). Although this method is effective, it is generally more complex than DC motor control. As a result, DC motors are often preferred for variable-speed applications, while AC motors are more commonly used in constant-speed and continuous-operation systems.

5. Maintenance and Durability

DC motors, especially brushed models, may require more maintenance because their brushes and commutators wear over time. Meanwhile, AC motors, particularly induction types, are brushless and simpler in design, using a stator and rotor without mechanical commutation. This makes them generally more durable and maintenance-free for long-term use.

6. Emerging Hybrids: BLDC & VFD AC

The line between DC and AC is blurring with modern electronics. As motor technology advances, hybrid solutions are emerging that blend the strengths of both worlds. Brushless DC motors (BLDCs) take the core idea of DC control and merge it with a permanent-magnet rotor and fully electronic commutation. By eliminating brushes and mechanical wear points, BLDC motors deliver clean, efficient, and precise performance.

On the AC side, VFDs have revolutionized the way induction motors operate. By adjusting the supply frequency and voltage in real time, a VFD allows an AC motor to achieve true variable-speed control. This narrows the performance gap with DC motors while dramatically improving energy efficiency. These technological advances make both BLDC and VFD-controlled AC motors a versatile and efficient choice for various modern applications.

Advantages and Limitations

DC motors are compact and offer easy, precise speed control; however, they are limited to DC power sources, and brush wear can reduce their lifespan and increase maintenance requirements. Alternatively, AC motors are robust, simple in design, low-maintenance, and highly efficient for continuous, heavy-duty industrial use. They are easier to install and operate where AC power is readily available, though their speed control is generally less flexible and more complex.

| DC Motor | AC Motor | |

| Pros | Easier speed control High starting torque Great for dynamic loads |

Simple, robust, and durable Lower maintenance Easy installation and integration Ideal for large-scale industrial use |

| Cons | Requires DC power Brushes wear out Higher maintenance Sparks from commutators limit use |

Limited speed control Lower starting torque. Synchronous motors need complex excitation systems |

Applications

DC motors excel in applications where precise control and compact size are important, ranging from tiny vibration motors in smartphones to precision robotics and electric vehicle drivetrains.

AC motors are robust and durable, designed for heavy-duty, continuous operation with minimal maintenance. They dominate in factories, power plants, HVAC systems, compressors, pumps, conveyors, and other industrial machines where reliable, constant-speed performance is critical.

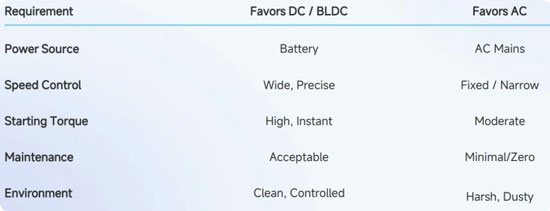

How to Choose the Right Motor

If you care about compact size, precise speed control, or running on batteries, a DC motor is your best bet. They’re also great when you need high starting torque and easy speed regulation, which is why you’ll often find them in robotics, small gadgets, and electric vehicles.

At the same time, if durability, low maintenance, and long-lasting performance are your top priorities, AC motors take the lead. They shine in applications powered by the grid, especially in heavy-duty industrial setups like pumps, conveyors, HVAC systems, and other machinery that needs to run reliably day in and day out.

In short, go for DC motors when you need control and compactness, and choose AC motors when you need robustness and long-term reliability.

Conclusion

Choosing between DC and AC motors ultimately depends on your specific application and priorities. DC motors are ideal for situations where compact size, precise speed control, battery operation, or high starting torque is required, making them perfect for robotics, small devices, and electric vehicles. AC motors, on the other hand, excel in durability, low maintenance, and long-term reliability, making them the preferred choice for industrial machinery, HVAC systems, pumps, and other continuous-operation applications.

For more detailed specifications, product options, and technical guidance on both DC and AC motors, visit the ATO.com to explore their full range of motor solutions and find the right fit for your needs.