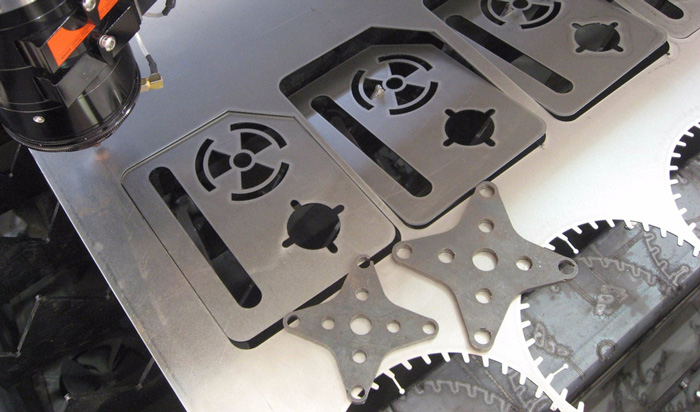

Fiber laser cutter for sheet metal working

The traditional cutting technology includes flame cutting, plasma cutting, water jet cutter cutting, linear cutting, punch processing and so on. As an emerging technology in the recent years, laser cutting irradiates the laser beam with very high energy density to the workpiece ready to be processed, so that the locality will be heated and melted. Then high-pressure gas is used to blow away the slag and form the cutting seam. The laser cutting has the following advantages:

- Narrow slot, high precision, good roughness of the slot, no need to be processed by the following procedures after cutting.

- The laser processing system itself is a computer system. It can be convenient for compiling and modifying. Therefore, it is convenient for personal processing, especially for the sheet metal parts with complicated shapes and outlines. Because of the numerous batches and small lot sizes as well as the short product life cycle, balanced from the technology, economic cost and time aspects, the mold manufacturing is not cost-effective. The laser cutting has extremely good advantages.

- The energy density of laser cutting is rather high, with short acting time, small heat influential area, small heat deformation and small thermal stress. Furthermore, because laser is non-contact mechanical processing, it has no mechanical stress to the work piece. It is suitable for the precise processing.

- The high energy density of the laser is enough to melt any metal, especially appropriate for the materials with high hardness, high fragility and high melting point which are difficult to be processed by other technological means.

- Cheap processing cost. The one-time investment of the device is rather expensive. However, the continuous and vast processing will finally reduce the processing cost of each component.

- The laser is non-contact processing, with small inertia and fast processing speed. Coordinated with the CAD/CAM software programming of the digital system, it is timesaving, convenient and efficient.

- The automation degree of the laser is rather high. It can process totally enclosed. It has no pollutant and small noise. It will improve the working environment of the operators greatly.

The advantages of the fiber laser cutting, compared with the laser cutting in the early period.

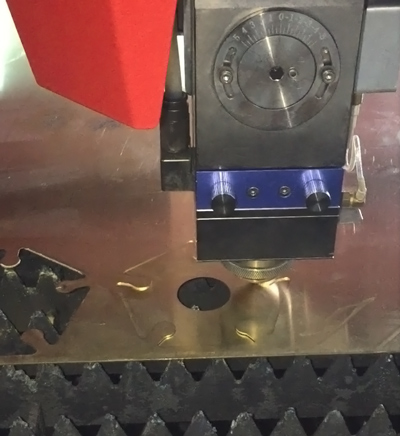

- The laser is transferred to the focusing head through the fiber. The flexible connecting mean is convenient to assort with the production line and realize the automation process.

- The ideal beam quality of the fiber improves the cutting quality and working efficiency greatly.

- The extremely high stability and super long life of the pumping diode of the fiber laser decides the fact that it doesn't have to regulate the current to adapt to the xenon arc aging like the traditional pumping laser, so as to improve the production stability and product consistency greatly.

- The photoelectric conversion efficiency of the fiber laser is more than 25%. The system has little power consumption, small volume and covering land.

- Compact structure, high system integration, fewer failures, simple and easy operation, no need for optical regulation, little maintenance and even zero maintenance, really realize "making achievements once settled". Combined with the anti-impact vibration and dust-proof performance, it is really suitable to be applied in the industrial processing area.

At present, the combination of the big breadth & fiber laser is put forward according to the characteristics of the metal plate industry to cut, thus solving the above-mentioned problem thoroughly and effectively. Its main design philosophy is as follows:

First of all, the fiber laser is used to replace the CO2 laser and light pump laser.  The fiber laser technology is a laser technology with fast development in the recent years. Compared with the traditional laser, it possesses better cutting quality, lower systematic cost, longer operation life and lower maintenance cost as well as the lower power consumption. In addition, the fiber laser can be transferred through fiber, which is convenient for the connection with the motion platform, so as to realize flexible processing and simplify the system design of the traditional laser cutting machine. It also improves the stability of the system and reduces the maintenance quantity. It is really appropriate for the application of the industrial processing area.

The fiber laser technology is a laser technology with fast development in the recent years. Compared with the traditional laser, it possesses better cutting quality, lower systematic cost, longer operation life and lower maintenance cost as well as the lower power consumption. In addition, the fiber laser can be transferred through fiber, which is convenient for the connection with the motion platform, so as to realize flexible processing and simplify the system design of the traditional laser cutting machine. It also improves the stability of the system and reduces the maintenance quantity. It is really appropriate for the application of the industrial processing area.

Secondly, based on the characteristics of the metal plate industry, most work pieces are thin plates with thickness controlled within 2mm. If the fiber laser of 200w-300w is matched optionally, the speed of cutting the thin carbon steel plate can reach 5-6 meters per second, which is equivalent to the practical processing speed of the CO2 laser cutting system in 2000w. However, the production cost of the laser system has been reduced greatly. As to the precision of the bed, in consideration of the precision requirement of the most sheet metal parts, usually the positional precision is designed around 100 um, which has also reduced the cost of manufacturing the bed. Of course, the users can also equip products with higher power level and positioning precision as optional according to the different material and thickness of the work piece as well as the precision requirement.