How Does a Float Switch Work?

The float switch is a simple structure, easy to use level control device, it does not need to provide power, there is no complex circuit, it is than the general mechanical switch volume is small, long working life, and other advantages. Float switches are widely used in the shipbuilding industry, generator equipment, petrochemical industry, food industry, water treatment equipment, dyeing and finishing industry, hydraulic machinery, etc. One-stop Industrial Automation shop will give you a detailed introduction to how float switches work and its working principle.

Structure

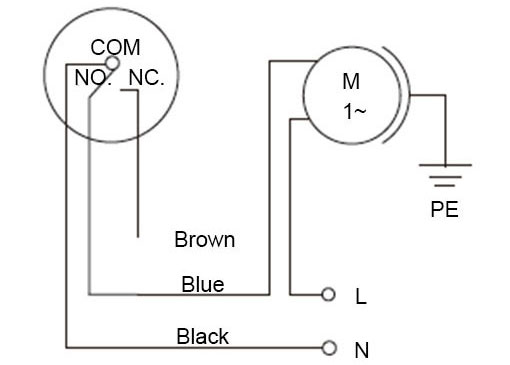

Float switches usually consist of two main parts: The float and the switching assembly. The float is a lightweight floating object, usually round or oval in shape, and can be made of plastic or stainless steel. The switch assembly is usually located below the float and consists of the circuitry and electrical contacts.A float switch is a small, simple, convenient, and practical tool for measuring liquid levels. A straight-mounted float switch consists of a straight rod with a float strung in the center, one or more reed switches are placed into the hollow rod, noting that the position of the reed switch is the switch position, and then filled with glue.

The float has a permanent magnet in it, and the float floats up and down with the liquid level to sense the reed switches, so that the liquid level can be detected. Side-mounted float switch also has a main body rod, a float, the float will be installed in the rod, similar to the lever, the float floats up and down with the liquid level to achieve the role of detecting the liquid level. Float switch output switch signal (1/0), wiring is also very simple, two wires out of the line into the control line, it will be used as a switch. However, due to the limitation of reed switch parameters, it can not be connected to high-voltage lines, and can not be loaded with motors, motors and other high-power devices.

Principle of Operation

The working principle of the float switch is based on Archimedes' principle, i.e., when an object is immersed in a liquid, it is subjected to an upward buoyant force equal to the weight of the liquid being discharged. At the same time, the object is subjected to a downward gravitational force in the liquid equal to the weight of the object. When the buoyant force equals the gravitational force, the object will remain at a specific depth in the liquid, and this is the equilibrium point upon which the operation of a float switch is based.

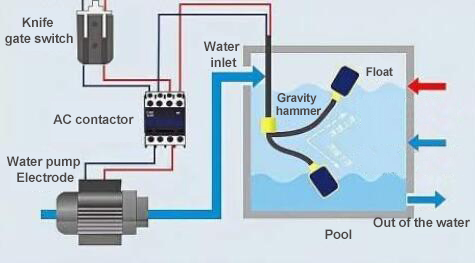

Float switches operate magnetically, with no mechanical connections, making the float switch operation simple and reliable. When the float switch measures media float, float drives the main body to move, while the float at the other end of the magnet will control the rod on the magnet switch action. Float switches are adapted to control pump operation to maintain the level, control the automatic loading and unloading of tanks, and control the level or supply signals, such as tanks, automatic cleaning systems, hydraulic tanks, low-pressure boilers, and sewage treatment systems.

The technical advantage of float switches is that float switches do not contain components such as bellows, springs, seals, etc. that cause failures to occur. Instead, a straight float is used to drive the switch's internal magnet, and the float switch's simple lever allows the switch to act instantaneously. The float cantilever angle limit design prevents the float from being vertical.

Working Process

When the water level of the liquid rises, the float will rise with it, as the buoyancy force increases and exceeds the gravity of the float. At this point, the float will rise to a specific position until the buoyancy and gravity are balanced. When the level drops, the float will sink as the buoyant force decreases and is less than the gravity of the float. The float will continue to fall until the balance between buoyancy and gravity is reached again. The float will continue to rise and fall at different liquid levels, and the control of the float switch is realized according to the change in liquid level.

The lower portion of the float switch includes electrical contacts to control the on/off of the circuit. The contacts are usually located above the float or in a housing around the float. When the float rises to a specific height, the contacts close, creating a circuit path. When the float falls, the contacts open, interrupting the circuit. This change of state can be used to control the level sensor's output signal, such as turning a pump, alarm system, or indicator light on or off.

Application Areas

- Wastewater Treatment: The float switches for monitoring and controlling the level of sewage and wastewater to ensure proper treatment and discharge.

- Drinking and Industrial Water Treatment: The float switches for monitoring the water level in tanks, pools, or troughs to ensure smooth operation of the water supply and treatment process.

- Oilfield and Petrochemical: The float switches for monitoring fluid levels in oil wells, storage tanks, and chemical equipment to maintain production and safety.

- Automotive Industry: The float switches for level control in automotive coolant tanks to ensure proper engine operation.

- Hotel and Residential: The float switches for level control in water tanks to ensure water flow supply.

All in all, the float switch is a simple but effective level control device that works based on the principle of balance between buoyancy and gravity. It has a wide range of uses in various applications, but liquid characteristics, temperature, pressure, and maintenance requirements need to be considered when selecting and using it. With proper selection and maintenance, float switches can reliably monitor and control liquid levels to ensure smooth operation in a variety of industrial and commercial applications.