Air Pressure Regulator

1/4 Inch Rc Air Pressure Regulator

1/8 Inch Rc Air Pressure Regulator

1/2 Inch Rc Air Pressure Regulator

1/4 Inch Electro-Pneumatic Pressure Regulator, -1.3~80 kPa

1/8 Inch Digital Air Pressure Regulator, 50~1000 mbar

1/4 Inch Electronic Air Pressure Regulator, 50~5000 mbar

3/8 Inch Electric Pneumatic Pressure Regulator, 50~5000 mbar

1/2 Inch Electro-Pneumatic Pressure Regulator, 50~9000 mbar

3/8 Inch Proportional Electric Air Pressure Regulator, 50~9000 mbar

What is a air pressure regulator?

Air pressure regulator is to use compressed gas as the power source, the cylinder as the actuator, and use the valve positioner, converter, solenoid valve, retaining valve, gas storage tank, gas filter and other accessories to drive the valve to realize the opening and closing. Quantitative or proportional adjustment, receiving the control signal of the industrial automation control system to complete the adjustment of the pipeline medium: flow, pressure, temperature, liquid level and other process parameters. Pneumatic control valve is characterized by simple control, fast response, and intrinsic safety, without the need for additional explosion-proof measures.

How to install a air pressure regulator?

- The installation position of the pneumatic pressure regulating valve is required to have a certain height from the ground, and there must be a certain space above and below the valve to facilitate the disassembly and repair of the valve. For regulating valves equipped with pneumatic valve positioners and handwheels, it must be easy to operate, observe and adjust.

- The regulating pressure valve should be installed on the horizontal pipeline, and the top and bottom are vertical to the pipeline. Generally, it should be supported under the valve to ensure stability and reliability. For special occasions, when the regulating valve needs to be installed horizontally on a vertical pipeline, the regulating valve should also be supported (except for the small-diameter regulating valve). When installing, avoid adding additional stress to the regulating valve).

- The working environment temperature of the pressure regulating valve should be (-30 ~ + 60), and the relative humidity should not be greater than 95%.

There should be a straight pipe section at the front and rear of the regulating valve, and the length should not be less than 10 times the pipe diameter (10D), so as to avoid the straight pipe section of the valve being too short and affecting the flow characteristics. - When the diameter of the adjusting valve is not the same as that of the process pipeline, it should be connected with a reducer. Threaded connections can be used when installing small-diameter control valves. The fluid direction arrow on the valve body should be consistent with the fluid direction.

- To set up the bypass pipe. The purpose is to facilitate switching or manual operation, and the control valve can be repaired without stopping.

- Before installing the pressure regulating valve, thoroughly remove foreign matter in the pipeline, such as dirt, welding slag, etc.

How pneumatic regulator work?

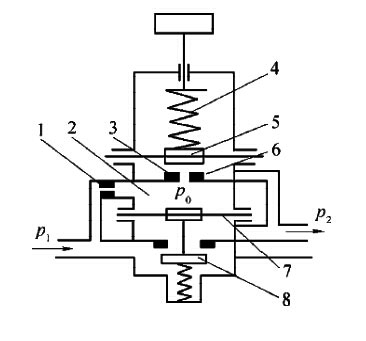

Pilot operated pressure reducing valve

When the output pressure of the pneumatic pressure regulator valve is high or the diameter is large, and the pressure regulating spring is used to directly adjust the pressure, the spring stiffness must be too large. When the flow rate changes, the output pressure fluctuates greatly, and the structural size of the valve will also increase. . To overcome these disadvantages, pilot operated pressure reducing valves can be used. The working principle of the pilot-operated pressure reducing valve is basically the same as that of the direct-acting type. The pressure regulating gas used in the pilot-operated pressure reducing valve is supplied by a small direct-acting pressure reducing valve. If the small direct acting pressure reducing valve is installed inside the valve body, it is called an internal pilot pressure reducing valve; if the small direct acting pressure reducing valve is installed outside the main valve body, it is called an external pilot pressure reducing valve . Compared with the direct-acting pressure reducing valve, the internal pilot pressure reducing valve adds a nozzle baffle enlargement link composed of the nozzle 4, the baffle 3, the fixed orifice 9 and the air chamber B. When the distance between the nozzle and the baffle changes slightly, the pressure in the B chamber will change significantly, which will cause the diaphragm 10 to have a large displacement to control the up and down movement of the valve core 6, so that the inlet The air valve port 8 is opened large or closed small, which improves the sensitivity of the valve core control, that is, the voltage regulation accuracy is improved.

Externally piloted pressure reducing valves work on the same principle as direct-acting. There is also a small direct-acting pressure reducing valve (not shown in the figure) outside the main valve body, which controls the main valve. This type of valve is suitable for occasions with a diameter of more than 20mm, long distances (within 30m), high places, dangerous places, and difficult pressure regulation.

Direct acting pressure reducing valve with relief valve

The compressed air with the pressure of P1 is input from the left end and throttled through the valve port 10, and the pressure drops to the output of P2. The size of P2 can be adjusted by the pressure regulating springs 2 and 3. Rotate the knob 1 clockwise, compress the springs 2, 3 and the diaphragm 5 to move the valve core 8 downward, and increase the opening of the valve port 10 to increase the P2. If the knob 1 is rotated counterclockwise, the opening of the valve port 10 decreases, and P2 decreases accordingly.

If P1 rises instantaneously, P2 will rise accordingly, so that the pressure in the diaphragm air chamber 6 will increase, and the thrust generated on the diaphragm 5 will increase accordingly. This thrust destroys the balance of the original force, making the diaphragm 5 upward When moving, a small part of the airflow is discharged through the overflow hole 12 and the exhaust hole 11 . When the diaphragm moves up, due to the action of the return spring 9, the valve core 8 also moves upward, and the intake valve port 10 is closed, the throttling effect is increased, and the output pressure is lowered until a new balance is reached, and the output pressure is basically back to the original value. If the input pressure drops instantaneously, the output pressure also drops, the diaphragm 5 moves down, the valve core 8 moves down accordingly, the intake valve port 10 is opened larger, the throttling effect is reduced, and the output pressure basically returns to the original value. Turn knob 1 counterclockwise. The regulating springs 2 and 3 are relaxed, the thrust of the gas acting on the diaphragm 5 is greater than the force of the pressure regulating spring, the diaphragm is bent upward, and the intake valve port 10 is closed by the action of the return spring. Rotate the knob 1 again, the top of the intake valve core 8 will be disengaged from the overflow valve seat 4, and the compressed air in the diaphragm air chamber 6 will be discharged through the overflow hole 12 and the exhaust hole 11, so that the valve is in a state of no output.