Welding Machine

200A DC Arc welder, Dual Voltage 110V/220V

200A Tig Miller Welder AC DC 110V/220V

200Amp Stick Welder, DC Dual Voltage 110V/220V

50A DC Arc Plasma Cutter, Dual Voltage 110V/220V

80A Plasma Cutter Welding Machine, 220V

175A DC Mig Welder, 240V

1200W Ultrasonic Spot Welding Machine

ATO offers AC DC welding machines, dual voltage 110V 220V, 50/60Hz, support split input voltage 220V, low price plasma cutter, 200A miller mig welder, 200A stick welder and 175A mig welder for sale.

The welding machine uses the high-temperature arc generated by the positive and negative poles in an instantaneous short-circuit to melt the solder and the material to be welded on the electrode to combine the objects to be contacted. Its structure is very simple, portable welder it is a high-power transformer.

Arc Welding Machine Working Step:

- Setting up the machine. To begin, the welding machine must be set up. Various controls can be used to change the power of the machine and how it operates. It's important to read the manual provided by the manufacturer thoroughly to set up an arc welder properly.

- Grounding the welding material. Once the welder is ready to begin the welding process, they will attach a ground clamp to the metal workpiece. This attaches directly to the welding machine. This is essential because it helps complete the electrical circuit that will create the arc, which is used to join the two pieces of metal together.

- Placing an electrode lead against the welding material. When the welder is ready to begin the welding process,, they will place a highly conductive electrode against the welding material and activate the machine to send electrical current through the workpiece. The electrode may be a stick electrode or a piece of wire fed through a welding "gun" depending on the type of arc welding being performed.

- Forming the electrical arc. When the electrode is pulled away from the metal workpiece slightly, usually by about 2 to 4 millimeters, an electrical arc forms as electrical jumps between the metal and the electrode. This extremely hot arc begins to melt the metal workpiece and the electrode almost immediately.

- Melting the metals and joining them together. Once the arc has been formed, the metal workpiece and electrode will continue to melt together, forming what's called a "weld pool". This is a pool of molten metal that will form the joint between the metal that is being welded.

- Protecting the metal with shielding gas. At high temperatures, the oxygen and other gases in the atmosphere tend to react with the metal in the weld pool, and can cause imperfections that damage the quality of the metal joint.

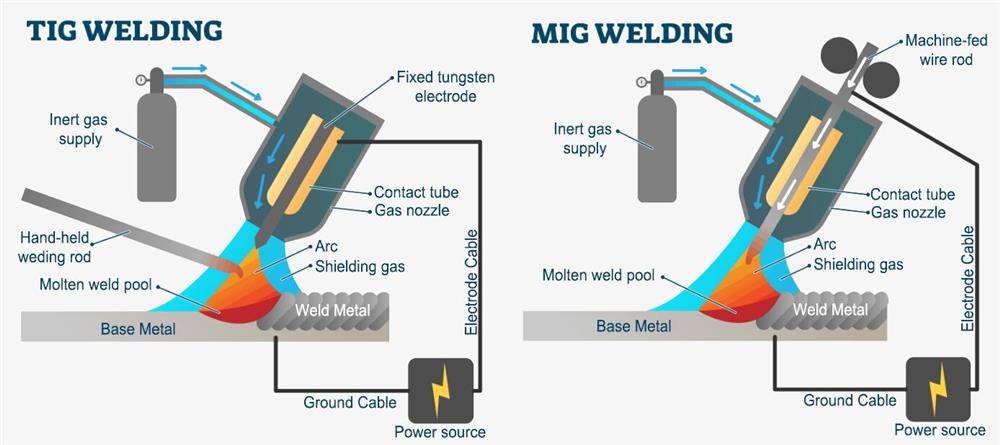

Difference Between Tig and Mig Welding:

Tig welding is highly versatile, enabling industry professionals to join a wide range of small and thin materials. It uses a non-consumable tungsten electrode to heat the metal and can be used with or without a filler. Compared to mig welding, it is much slower, often resulting in longer lead times and greater production costs. Additionally, welders require highly specialized training to ensure they achieve proper precision and accuracy. However, it also offers greater control during the welding operation and produces strong, precise, and aesthetically pleasing welds.

Mig welding is generally used for large and thick materials. It employs a consumable wire that acts as both the electrode and the filler material. Compared to tig welding, it is much faster, resulting in shorter lead times and lower production costs. Additionally, it is easier to learn and produces welds that require little to no cleaning and finishing. However, its welds are not as precise, strong, or clean as those formed by tig welding operations.

Types of Welding Methods:

Numerous techniques and technologies have been developed to optimize the welding process for different materials and products, including 5 types:

- Arc welding uses an electrical current to weld metals. Types of arc welding include metal inert gas (MIG) welding and tungsten inert gas (TIG) welding, among others.

- Friction welding melts the bonding and base material through mechanical friction. This process can be used with thermoplastics and metals.

- Electron beam welding uses a stream of electrons to melt materials into a joint. This process must be completed in a vacuum and is typically used for thicker components.

- Laser welding is a high-speed process that employs a laser to melt and join metals and/or thermoplastics together.

- Resistance welding uses heat generated between electrodes or rotating wheels to melt and join the base materials. Types include spot welding and seam welding.