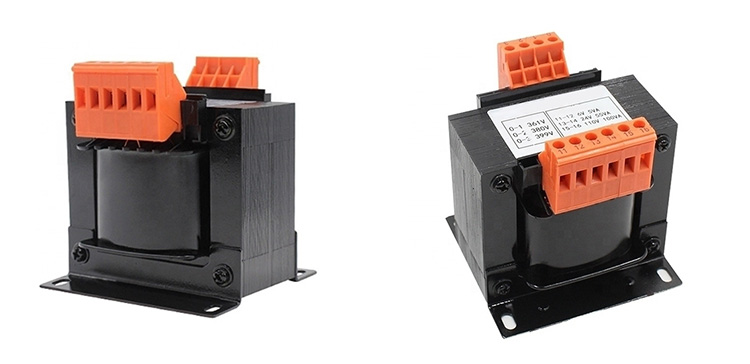

Control Transformer: Definition, Advantage and Application

In low voltage distribution system, control transformer is named because it is used in control system. It is actually a step-down transformer with a variety of output voltages, and can also be used as a low-voltage lighting and signal lamp, indicator power supply.

In order to better understand the control transformer, ATO industrial automation will introduce you from three aspects.

Definition:

This type of circuit is a special circuit that is designed to control the working of a power circuit. Control circuits are supplied from an A.C source, control transformers can be used for supplying the control circuits. Such power transformers have separate windings. Conductors of control circuits directly connected to the supply voltage and of circuits supplying control circuit transformers must be protected against overcurrent. Conductors of the control circuits supplied by a control circuit transformer or DC supply must be protected against overcurrent.

The primary winding of a industrial control transformer is connected to the line voltage, while the secondary winding is connected to the control circuit. The secondary voltage is typically much lower than the primary voltage and is designed to match the voltage requirements of the control circuit.

Advantage:

- Isolation. One of the primary advantages of a control transformer is that it provides electrical isolation between the primary and secondary windings. This helps to ensure that the control circuit is isolated from the high voltage power circuit and eliminates any risk of electrical shock or damage to the control circuit.

- Voltage regulation. Control power transformers are designed to provide a stable and regulated output voltage to the control circuit. This helps to ensure that the control circuit operates reliably and accurately, even when there are fluctuations in the input voltage.

- Efficiency. They are typically highly efficient, which means that they consume less power and generate less heat than other types of transformers. This helps to reduce energy costs and prolong the life of the transformer.

- Size and weight. Control transformers are typically smaller and lighter than other types of transformers. This makes them easier to install and transport, and also helps to save space in electrical cabinets.

- Cost. Control transformers are generally less expensive than other types of transformers. This makes them a cost-effective solution for providing power to control circuits in a wide range of applications.

Application:

- Control circuits for motors. Control power transformers are used to power the control circuits for electric motors. These circuits include motor starters, overload relays, and other protective devices.

- HVAC systems. Control transformers are used in heating, ventilation, and air conditioning (HVAC) systems to power the control circuits for the various components such as fans, pumps, and dampers.

- Lighting circuits. They are used to power the control circuits for lighting systems, including emergency lighting, dimming controls, and photocells.

- Industrial automation. Control transformers are used in industrial automation systems to power the control circuits for various machines and equipment, such as conveyors, packaging machines, and robotic systems.

- Process control systems. Control voltage transformers are used to power the control circuits for process control systems in industries such as chemical processing, food and beverage, and pharmaceuticals.

- Building automation. They are used in building automation systems to power the control circuits for lighting, HVAC, and security systems.