How does a HMI Control VFD?

HMI, short for human machine interface, is a medium for interaction and information exchange between systems and users, which realizes the conversion between the internal form of information and the form acceptable to humans. Human-machine interfaces exist in all fields that participate in the exchange of human-machine information. So, how do HMI and PLC control VFD?

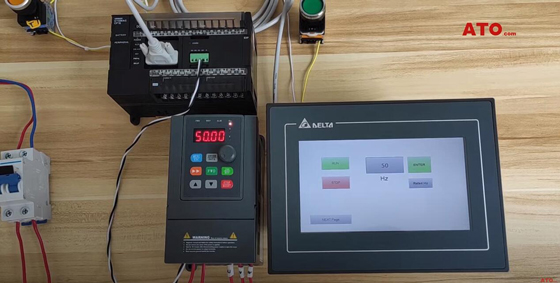

PLC communicates with HMI through RS232 interface.

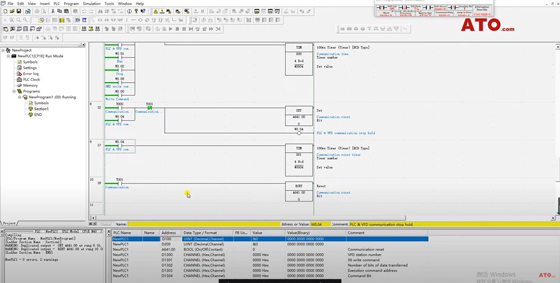

View PLC memory data.

D100 (frequency storage area), D200 (RUN&STOP command storage area), D1300 ~ D1304 (Modbus RTU instruction storage area) are cleared.

Enter 60Hz in the HMI and press “ENTER”.

We can see that the display frequency on the VFD has been modified to 60Hz.

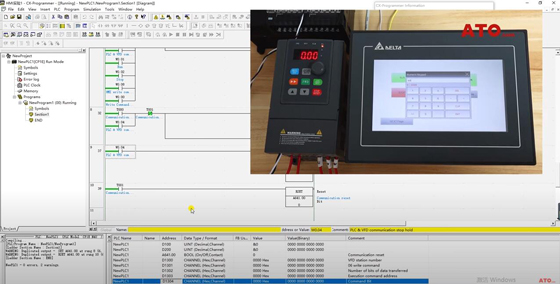

Enter 30Hz in the HMI and press “ENTER”.

The VFD display is modified to 30Hz, and the value in the PLC D100 storage area is 3000 (30.00Hz).

When pressing “Rated Hz” of HMI, the frequency of VFD is modified to 50Hz.

Press “RUN” on the HMI, the VFD starts to run and the motor starts to rotate.

D1300 ~ D1304 execute Modbus RTU instruction.

The VFD 2000H address executes the run command 0001.

Press “STOP”, VFD executes the 0007 stop command, and the motor stops.

We check the next page function of HMI and the function of returning to the previous page.

Press the HMI system setting displayed in “System”.

You can view the video below to learn more about how to control a VFD through HMI and PLC.