How Does Float Level Switch Work & Wire?

The float switch is a liquid level control device with simple structure and convenient use. It does not need to provide power supply and has no complicated circuit. It has the advantages of smaller size and longer working life than ordinary mechanical switches. When selecting the model, as long as the material is selected correctly, any liquid or pressure and temperature can be used. It can be used in shipbuilding industry, generator equipment, petrochemical industry, food industry, water treatment equipment, dyeing and finishing industry, hydraulic machinery, etc a wide range of applications.

How a float switch works?

The float switch is controlled to open or close according to the buoyancy of the magnetic ball in the water, and the magnetic ball moves up and down with the increase or decrease of the water volume. When the water volume reaches the set water level, the magnetic ball will press against the corresponding position, so that the water will not flow into the water tank; when the water volume decreases, the magnetic ball will move down, and the water will automatically flow into the water tank, completing the float switch once.

The float switch does not need a power supply, its power is the magnetic force, and no additional mechanical connecting parts are needed. Its structure is a float, a main body and a magnet. When the measured object of the float switch floats the float, the float will start to move under the influence of buoyancy, and the main body will also move up. At this time, the magnet at the other end will control the switching action of the main body rod.

The float level switch needs to re-calibrate the water level line before installation to ensure that it is consistent with the water level line of the thermal equipment during the installation process. It should be noted that the operating temperature of the switch such as high liquid level is high, so that the water temperature inside is also high. The density of water is lower than that of indoor warm water, so that the action line of room temperature water is lower than the switch identification line. The low liquid level alarm is connected to the normally closed (NC), and the high liquid level is connected to the normally open (NO).

The magnetic float of the floating ball liquid level switch moves up and down with the liquid level, so that the reed switch chip at the set position in the sensor detection tube moves, and sends out the conversion signal of the contact switch. Generally, one or more reed switches are installed in a closed non-magnetically conductive tube, and the tube is passed through one or more hollow floating balls with ring magnets inside. The rise or fall of the liquid will drive the floating balls to move up and down together. The dry reed switch in the non-magnetic-conductive tube can be pulled in or disconnected, thereby realizing the function of outputting a switch signal.

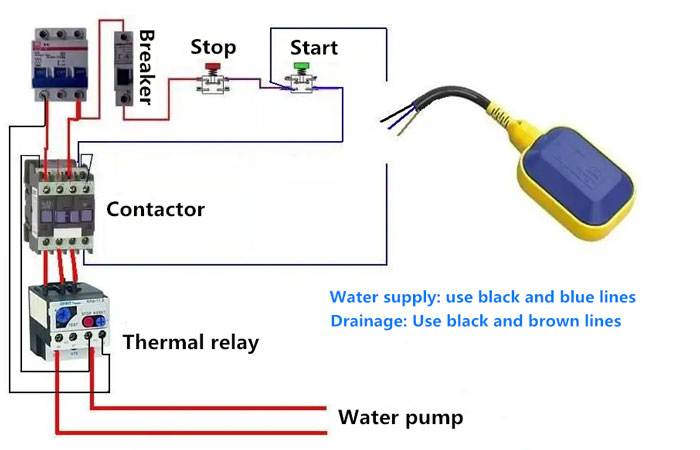

How to wire float switch?

As shown in the figure, the float level switch has three lines of black, blue and brown. When supplying liquid, connect the two lines of black and blue. When the liquid is low, the switch is turned on, and the switch is turned off when the liquid is high. Connect the black and brown lines when the liquid is drained, the switch is turned on when the liquid is high, and the incoming pipe is disconnected when the liquid is low.

The control height of the liquid level is determined by the length of the cable in the liquid and the position of the weight. The method of fixing the weight is to remove it from the non-flare section, put it on the appropriate position of the cable, and then connect the cable. Pass through the end of the hammer horn.