Introduction of Push Button Switch

What is push button switch?

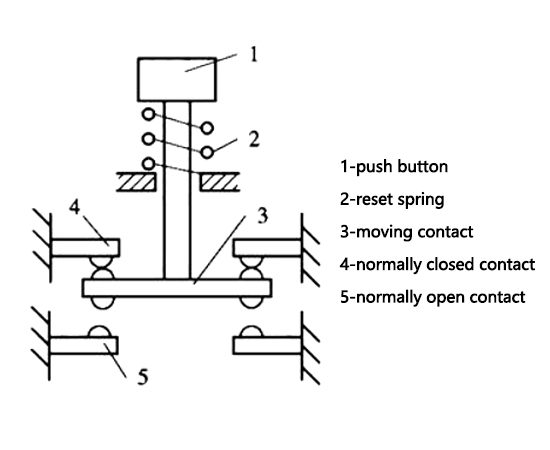

Push button switch refers to a switch that uses a button to push the transmission mechanism, presses or disconnects the moving contact and the static contact, and realizes the circuit switching. It is a kind of electrical appliances with simple structure, composed of a metal shell and a circuit, in the electrical automatic control circuit, it is used to manually send out control signals to control contactors, relays, electromagnetic starters, etc. The working principle of the button: after the power is turned on, it outputs a high level signal, when the button is pressed, the button outputs a low-level signal in the normal state.

The structure type of the push button switch

The structure type of the push button switch

The push button control switch can be divided into self-locking type, self-resetting type, rotary handle type, mushroom head type, indicator light type, light symbol type and twist switch type. There are 1NC/ 1NO+1NC/ 2NC+1NO/ 2NO+1NC contact forms push button and different combinations. They generally adopt a building block structure. They are composed of button caps, return springs, bridge contacts and shells. They are usually made of composite type, with a pair of normally closed contacts and normally open contacts, some products can increase the number of contact pairs by connecting multiple elements in series. There is also a self-holding button, which automatically maintains the closed position after being pressed, the push button control box can only be opened after the power is cut off.

Selection principle of push button switch

Selection principle of push button switch

① Select the form of the card tube according to the purpose, such as emergency type, key type, instruction type, etc.

② The type of push button switch can be selected according to the use environment, such as open type, waterproof type, anti-corrosion type, etc.

③ The color of the push button switch box can be selected according to the requirements of working status and working conditions.

Installation and use of push button switch

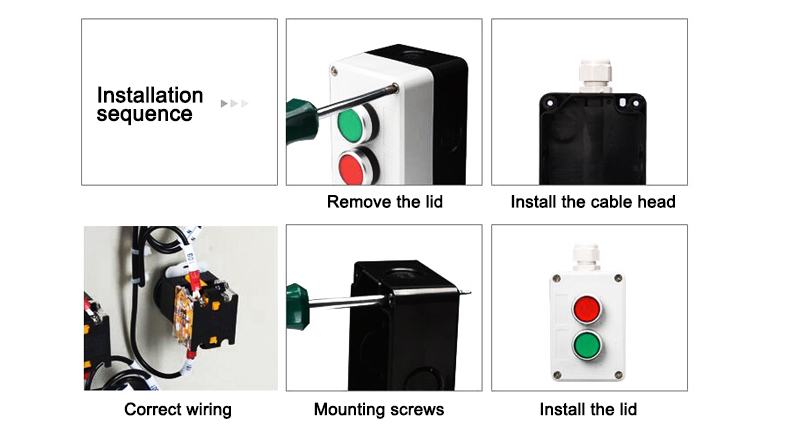

1. When installing the push buttons switch on the panel, neatly arrange them in a reasonable way. They can be arranged from top to bottom or from left to right according to the motors' start order.

2. The installation and fixing of the button should be firm, and the wiring should be reliable to avoid confusion. Apply the red button to stop, green or black to start or power on.

3. Due to the small distance between the button contacts, short-circuit failures are likely to occur if there is oil stains, so the contacts should be kept clean.

4. The button board and button box must be metal, and try to connect them to the machine's general grounding bus. For the suspended button, a dedicated grounding wire must be provided, and metal pipes must not be used as the grounding wire.

5. When the push button switch box is used in high temperature occasions, it is easy to cause plastic deformation and aging to cause looseness, causing a short circuit between the terminal screws. An insulating plastic tube can be added to the terminal screws to prevent short circuits.

6. The push button with indicator light will easily deform the plastic lampshade due to the heat generated by the bulb. The voltage of the bulb should be lowered to prolong the service life.

7. The "stop" push button must be red, and the "emergency stop" push button must be a red mushroom head type, the "start" button must have a protective retaining ring, which should be higher than the button head to prevent accidental touch and electrical equipment from malfunctioning.

The function of the emergency push button switch

The function of the emergency push button switch

The emergency stop button is a measure that people can quickly press this button to achieve protection when an emergency occurs.

In various factories, eye-catching red buttons can be seen on some large and medium-sized machinery and equipment or electrical appliances. The standard ones should have red fonts that have the same meaning as "emergency stop". Such buttons can be collectively referred to as emergency stop buttons. This button can be directly pressed down to quickly stop the whole equipment or release some transmission parts. If you want to start the device again, you must release this button, that is, you only need to turn it clockwise about 45° and then release it, and the pressed part will bounce.

In industrial safety, it is required that all machines whose transmission parts directly or indirectly cause harm to the human body under abnormal conditions must be protected. The emergency stop button is one of them. Therefore, the emergency stop button must be added when designing some machines with transmission parts. And it should be set on the surface of the machine that can be easily pressed by personnel, and there should be no obstructions.

Selection of NO and NC contact form for Emergency push button Switch

The most basic function of the emergency stop button is to stop in an emergency to avoid mechanical accidents or personal accidents. However, due to the long-term operation of the machine, the line, especially the emergency stop line part, may cause a fault and open circuit. At this time, if the emergency stop button uses a normally open contact, the line fault of the emergency stop part will not be found. If the emergency stop button is used then it will be too late. When using normally closed contacts, when the emergency stop part of the circuit fails, it will at most cause the machine to stop, and the loss will be relatively small. When designing an electrical control system, it is best to use a normally closed contact for the emergency stop button, so that the safety factor is relatively high.