What is a Protractor?

Protractor, also known as universal bevel protractor. It is an angle measuring instrument that uses a movable ruler to measure the rotation of the surface relative to the measuring surface of the base ruler, and reads the angle separating the two measuring surfaces. It is an angle measuring tool used to measure the internal and external angles of precision parts or to perform angle marking. It is suitable for measuring internal and external angles in mechanical processing, and can measure 0 ° -320 ° external angles and 40 ° -130 ° internal angles.

Type of Protractor

According to its design, functionality, and display methods, it can be divided into several different categories:

- Vernier bevel protractor

- Dial protractor

- Digital protractor

Working Principle of Protractor

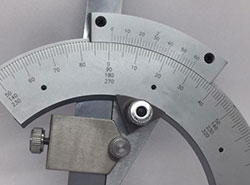

Protractor is a  measuring tool used to measure the internal and external angles of a workpiece. The reading is made based on the principle of a vernier, with each grid of the main ruler being 1 °. The vernier's grid is divided into 30 grids by 29 ° of the main ruler. Using 29 °/30=58 ', 58' is the degree of each grid of the vice ruler vernier. 1 ° -58 '=2 ', 2 'is the difference between the main ruler and the vernier, which is the accuracy of this ruler. The reading method is identical to that of a vernier caliper.

measuring tool used to measure the internal and external angles of a workpiece. The reading is made based on the principle of a vernier, with each grid of the main ruler being 1 °. The vernier's grid is divided into 30 grids by 29 ° of the main ruler. Using 29 °/30=58 ', 58' is the degree of each grid of the vice ruler vernier. 1 ° -58 '=2 ', 2 'is the difference between the main ruler and the vernier, which is the accuracy of this ruler. The reading method is identical to that of a vernier caliper.

Reading and Usage Method of Protractor

Reading method

When measuring, adjust the position of the square or ruler according to the condition of the product's measured part, fasten them with screws on the clamp block, and then adjust the angle between the measuring surface of the base ruler and other related measuring surfaces. At this point, first loosen the nut on the brake head, move the main ruler for coarse adjustment, and then turn the micro device on the back of the fan-shaped plate for fine adjustment until the two measuring surfaces are closely aligned with the measured surface. Then tighten the nut on the brake and take off the angle gauge for reading.

Usage method

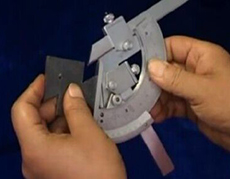

Preparation before measurement:

- Firstly, clean the surface of the protractor before use.

- Secondly, the workpiece is deburred and chamfered, and the measuring surface is wiped clean.

- Furthermore, holding the workpiece with the left hand, holding the universal square with the right hand, and holding the thumb and index finger of the left hand between the base ruler and the workpiece (i.e. not allowing the workpiece or universal square to move back and forth), the measurement method is the same as that of a knife edge square.

How to measure in different angles:

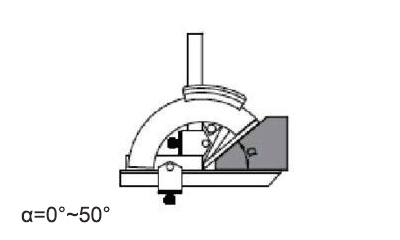

- Measurement of angles between 0 ~ 50°

The angle ruler and straightedge are all loaded, and the measured part of the workpiece is placed between the base ruler and the straightedge for measurement.

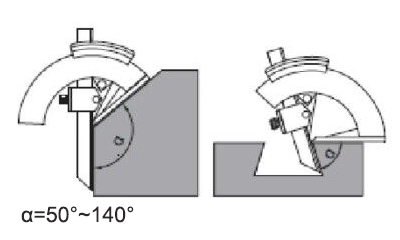

- Measurement of angles between 50° ~ 140°

The angle ruler can be removed, the straightedge is mounted so that it is connected with the sector plate, and the measured part of the workpiece is placed between the base ruler and the straightedge for measurement.

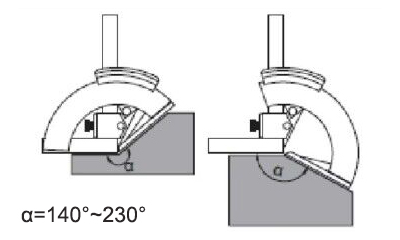

- Measurement of angles between 140°~230°

Remove the straightedge and the block and install the angle ruler so that it is aligned with the sharp edges of the base ruler of the sector plate, and the measured part of the workpiece is placed between the base ruler and the short side of the angle ruler for measurement.

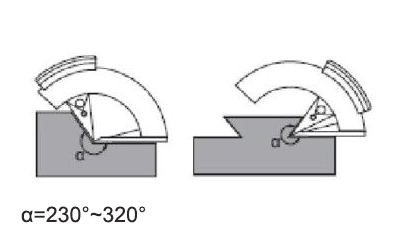

- Measurement of angles between 230 ° ~ 320 °

Angle ruler, ruler, card block can be removed, leaving only the sector plate and the base ruler, the measured part of the workpiece is placed between the base ruler and the measuring surface of the sector plate measurement.

Precautions and Maintenance

- When the protractor is damaged, it is not allowed to repair it with tools such as hand hammer and clanging knife, it should be handed over to the professional repair department for repairing, and it is allowed to be used only after it is qualified by the inspection after repairing.

- Do not use gauze or ordinary abrasive (emery) to wipe off the rust and dirt on the surface of the scale.

- It is not allowed to make steel seals or marks at the graduation line of the angle ruler to avoid inaccurate marking. If necessary, it is allowed to use electric or chemical etching methods to etch the marks.

- Do not place the protractor near the magnetic field to avoid magnetization of the caliper.

- The protractor should be wiped clean and placed flat after use to avoid deformation.

- Do not stack the protractor with other tools. Place the protractor in a dedicated measuring tool box to prevent contamination or rust.

- If the protractor is not used within a week, rust prevention treatment should be carried out.