What is a safety light curtain

The opening area needs to be set when constantly sending in and out parts on a dangerous high-speed operation machine. If a protective door is set here, it will seriously affect the production and certainly not be able to take both production and safety into account. Safety light curtain is a safety device set in these openings, and it realizes safety protection through the light beams. It is a type of sensor that install through beam photoelectric sensors in rows from top to bottom. It monitors a certain range of amplitude, when the machine is running, it intercepts the light when a human body intrudes, and stops the machine to achieve the purpose of protecting personal safety. However, when processed parts are fed in and out through the light curtain, they do not cause the machine to stop working. In this way, the operators are effectively protected from harm without affecting the production at the same time.

I. Safety light curtain principle

Safety light curtain consists of the light projector, light receiver, controller, transmission lines and power lines. Light signals are sent through the lightprojector installed inside a plurality of infrared emitting tubes, and the light receiving tube that is on the same line as the infrared emitting tube will receive the signals through its infrared receiving tube, which will form a protection curtain formed by infrared lights. The light detector monitors the on-off state of the light curtain, and the light curtain on-off signal will be processed through the internal circuit and directly output low level (pass through) or high level (blocked), and then connected to the PCL or alarm circuit through the transmission line, in order to stop the equipment or issue safety alarm.

Safety light curtain is different from the ordinary photoelectric sensors, area sensors, and ordinary light curtains. The area sensors and ordinary light curtains usually have detection blind spots. It is mainly because that they do not have a fault self-test function and cannot guarantee safety in the event of a fault. The safety light curtain does not have detection blind spot, and it can ensure safety in the event of failure due to the fault self-test function.

II. Safety features of safety light curtain

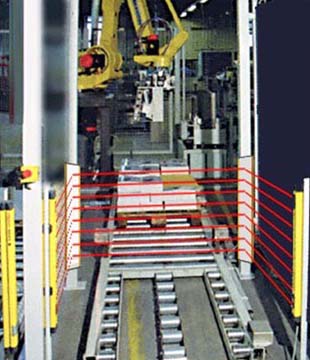

In reality, on one hand, when the AGV (automatic guided vehicle) sends the work piece into the hazardous area for processing, the hand of the robot works as usual, and its efficiency does not get affected. On the other hand, when the operator enters, safety light curtain should be able to detect the operator and control the robot to stop its operation to ensure the safety of the operator.

Therefore, depending on the way the AGV enters the hazardous area, the safety features of the safety light curtains are divided into:

- Shielding: The shielding function is a function that temporarily disables the safety function of the safety light curtain and keeps the control output ON even in the light-shielded state. This solves the problem that light curtain cannot be set because the AGV is passing through, which is both safe and productive. Of course, shielding can be dived into partial shielding and location shielding and other specific circumstances. In the process of shielding, in order to let people around know that the safety function is temporarily disabled, use the muting indicator (external indicator) to warn wherever the operator can confirm.

- Fixed blanking: Invalidate the specific optical axis of the safety light curtain. In this case, the control output remains ON regardless of the presence or absence of an object in the failure area.

- Floating blanking: When there are moving objects that do not want to be detected in the detection area, invalidate the detection function.