What Output Types Do Temperature Controllers Have?

In industrial automation, temperature controllers adjust heating or cooling equipment based on temperature changes through different output methods. They don’t just read temperatures—they actively respond to them. The output method determines how the controller interacts with heaters, coolers, and alarms. Choosing the wrong one can lead to energy waste, unstable temperatures, or even equipment damage. Therefore, precise temperature control is not just about accuracy—it also requires selecting the right controller output method for your specific application. Below, we will explore the seven primary output types of temperature controllers and their impacts on system performance, efficiency, and service life.

Control Output Types

7 Control Output Types of Temperature Controllers:

- Relay (On/Off) Output

- SSR Output

- PID Output

- Analog Output

- SCR Trigger Output

- PWM Output

- Digital Communication

Now, let’s take a closer look at the 7 different types of output that temperature controllers offer to suit a variety of applications.

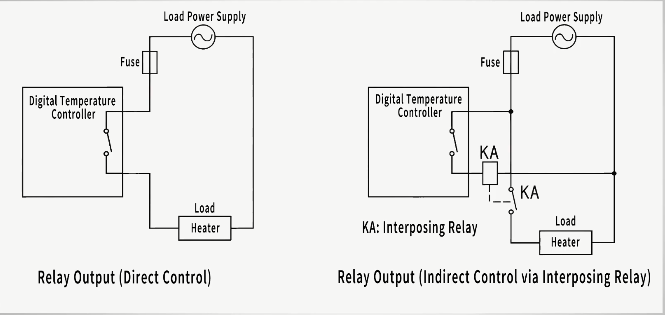

Relay (On/Off) Output

Relay output is a control mode that regulates temperature through ON/OFF switching, suitable for small loads (≤5A) or for driving contactors in high-power applications.

Features

- Simple ON/OFF control at set temperature

- Voltage-free relay contacts

- Low cost and easy to use

- May cause slight temperature fluctuations

- Limited switching life depending on usage

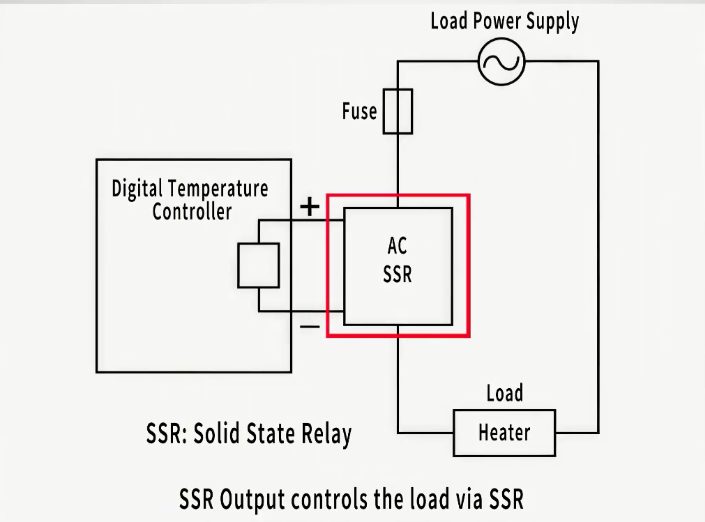

SSR Output

SSR output uses a DC voltage signal to drive external solid-state relays, enabling contactless ON/OFF control of high-capacity loads. Compared to mechanical relays, SSRs provide faster switching speed, longer lifespan, and higher reliability, making them ideal for applications that require frequent switching. They allow small control signals to handle larger loads, though the need for external SSR components may increase overall costs.

Features

- DC voltage pulse controls external SSR

- Handles large loads

- Fast, silent switching without mechanical contact

- Longer lifespan than mechanical relays

- Requires additional purchase, increasing overall cost

- Best for high-cycle applications

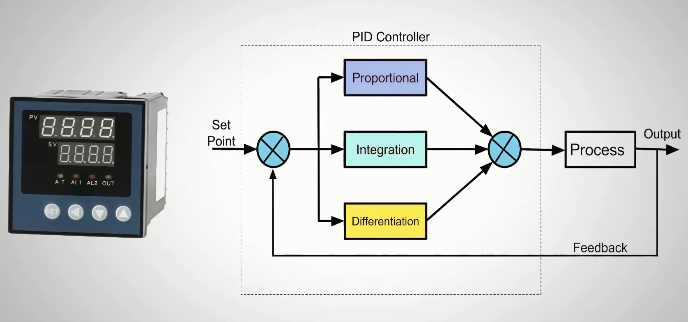

PID Output

The PID control method combines Proportional, Integral, and Derivative functions to deliver precise and stable temperature regulation. Proportional control adjusts output based on temperature deviation, Integral compensates for accumulated error over time, and Derivative anticipates future changes to reduce overshoot, making PID suitable for applications requiring high accuracy and stability.

Features

- PID Control: Proportional-Integral-Derivative Control

- Delivers the most precise and stable temperature control

- Can be tuned manually or automatically

- Best for precision-critical processes

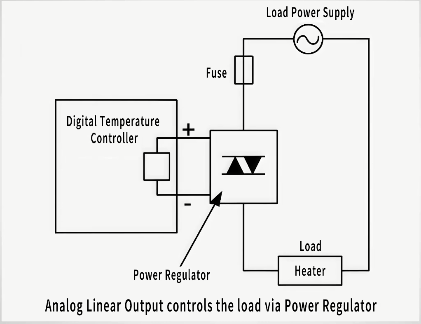

Analog Output

Analog output provides a continuous DC current (4–20mA) or voltage (0–10V) signal for precise, proportional load control. It enables more accurate temperature regulation than simple ON/OFF methods, making it suitable for applications demanding high accuracy, though it requires compatible actuators and may increase overall costs.

Features

- Provides continuous, proportional control signals

- Offers high precision in control

- Enables fine-tuned adjustment of load power

- Requires compatible actuators or controller

SCR Trigger Output

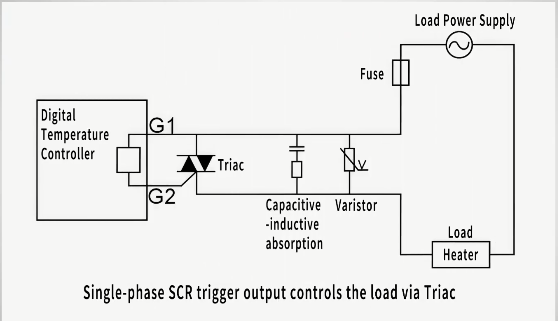

SCR trigger output sends zero-crossing or phase-angle signals to external SCRs for driving single-phase or three-phase loads. By adjusting conduction timing, it regulates load power—zero-crossing control changes average power at voltage zero points, while phase control modifies the start of each cycle. This method supports large loads with durability but may generate low-frequency noise and electromagnetic interference, often requiring extra filtering components.

Features

| 2 Trigger Modes | Application | Advantages | Challenge |

| Zero-cross | Better for resistive loads (heaters) | Direct high-power control Long service life |

Requires EMI suppression |

| Phase-angle | Ideal for inductive loads (motors) |

PWM Output

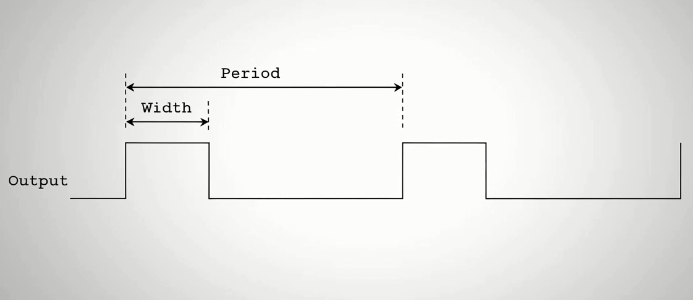

Pulse Width Modulation (PWM) output regulates power by generating a series of voltage pulses with varying widths, allowing fine-tuned control of energy delivery. It is versatile and can be applied in areas such as energy monitoring and driving external devices.

Features

- Works on rapid pulses to fine-tune power delivery

- Best for high-precision needs

- May be used in conjunction with external solid state relays

Digital Communication

Digital communication function supports RS485, and utilizes standard Modbus RTU communication protocol to allow for integration into automation systems.

Features

- Includes RS485, Modbus, Ethernet

- Enables smart factory integration

- Best for IoT-ready facilities with centralized monitoring

Choosing the Right Output

Selecting the right output for your application depends on load, precision, and budget:

1. Load Size: For loads under 5A, relays are sufficient. For larger loads, consider SSRs or SCRs.

2. Precision Requirement: Analog outputs are ideal for high-accuracy applications like laboratory equipment, while relays work well for general-purpose uses such as freezers.

3. Budget Considerations: Temperature controllers with built-in relays are more cost-effective, whereas systems using external SSRs offer longer lifespan and lower maintenance.

By considering these factors, you can match the appropriate output method to your needs, ensuring reliable, efficient, and cost-effective temperature control.

Conclusion

Temperature controllers provide a range of output options to suit different loads, precision requirements, and applications. From relays and solid-state relays to analog signals, PID control, SCRs, PWM, and digital communication, understanding their features helps you choose the right controller for accurate and efficient temperature regulation. Watch the video below for a visual demonstration of these output methods to guide your selection.