Hall Current Sensor: Working Principle and Application Mode

In each tourist attraction, we will see the existence of electric sightseeing buses, electric sightseeing buses use battery power supply driving mode, itself does not emit harmful gases polluting the atmosphere, only need to recharge the battery can be used, because most power plants are built far away from densely populated cities, less harm to human beings, and the power plant is fixed, centralized emissions, It is easier to reduce harmful emissions of all kinds and relatively mature technologies already exist. The electric sightseeing bus can make full use of the surplus electricity at night when the electricity supply is low, and the power generation equipment can be fully used day and night, which greatly improves its economic benefits and is conducive to saving energy and reducing carbon dioxide emissions.

Sensor is a kind of detection device, can feel the measured information, and can feel the information, according to certain rules into electrical signals or other required form of information output, to meet the information transmission, processing, storage, display, record and control requirements. Hall device is a kind of magneto-electric conversion device made of semiconductor material. In this article, ATO shop will introduce something about this type of current sensor.

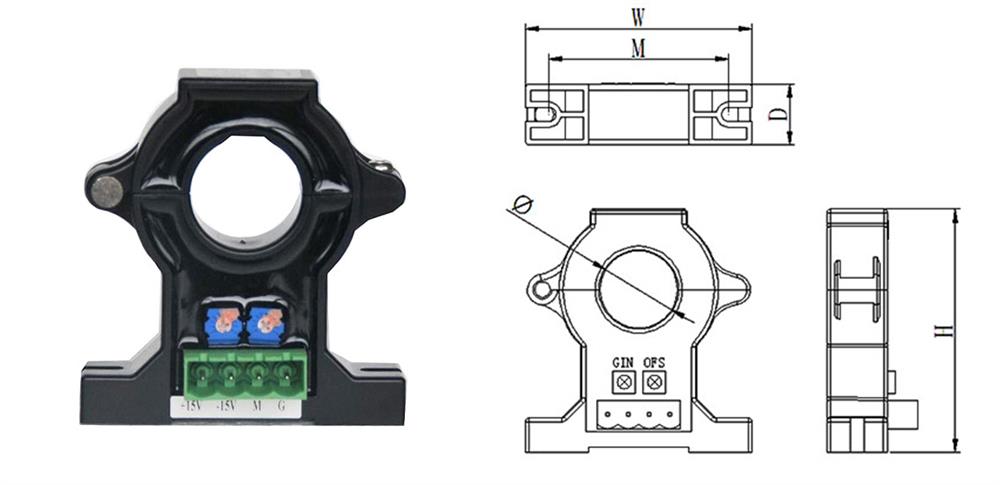

In the first, we will show the dimension and parameter of our hall current sensor.

| Model | ATO-AHKC |

| Zero offset voltage | ±20mV |

| Offset voltage drift | ≤±1.0mV/℃ |

| Linearity | ≤0.2%FS |

| Power supply | ±15VDC ±10% |

| Accuracy | 1.0%F.S. |

| Bandwidth | 0~20kHz |

| Response time | ≤5us |

| Work temperature | -25 ℃ ~ +70 ℃ |

Working Principle:

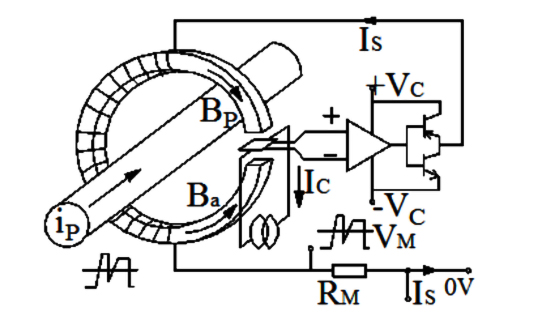

Hall current sensor is based on the magnetic balance Hall principle, that is, the closed-loop principle. When the high quality magnetic core generated by the primary side current is concentrated in the magnetic circuit, Hall element is fixed in the air gap to detect the magnetic flux, and output reverse compensation current through the multi-turn coil wound on the magnetic core to offset the magnetic flux generated by the primary side, so that the magnetic flux in the magnetic circuit is always maintained at zero. After special circuit processing, the output end of the hall current sensor can accurately reflect the current change of the original side.

Application Mode:

The current detection of the motor of the traditional electric sightseeing bus is usually measured through the Hall element, which is built into the rotor of the motor. Through the rotation speed and frequency changes of the motor, the feedback signal is timely, which is convenient for the operator to understand the working condition of the vehicle. Or some manufacturers will monitor through external shunt resistance, which will monitor the working state of the motor. However, due to the increasing use of electric sightseeing vehicles, and the emergence of similar electric patrol vehicles, electric tricycles, electric motorcycles and other products, the performance of the equipment itself is also increased, the traditional way is no longer competent for this work.

Under this condition, Hall closed-loop current sensor can be used to solve the relevant problems. The power line of the motor from the current sensor in the air through, when there is a current, the current sensor will be induced, and there will be a corresponding output, the output signal to the bus control system, centralized processing.

Using Tips:

- Pay attention to the exposed conductive part of the wiring terminal to prevent ESD (electro-static discharge) impact as far as possible. Engineers with professional construction experience are required to connect the product. The connecting wires of power supply, input and output must be correctly connected. Do not misposition or reverse connect. Otherwise, the product may be damaged.

- The installation and use environment of the product shall be free from conductive dust and corrosion.

- Violent vibration or high temperature may also lead to product damage, please pay attention to the use of the occasion.