How Does PWM Control LED Brightness?

Have you ever wondered why some desk lamps can change the brightness of the bulb from dim to bright by just turning the knob? In this article, ATO Online Store will delve into the dimming circuit inside these desk lamps and uncover the technological secrets behind them.

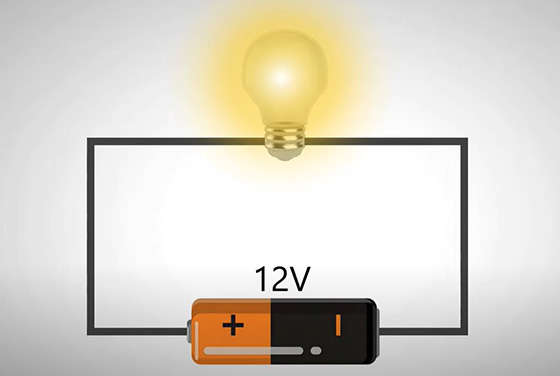

Basic Circuit

Let's take a bulb with a rated voltage of 12V as an example. To make the bulb light up normally, just connect a 12V power supply at both ends. But what if we want to control the brightness of the bulb? The simplest way is to connect a resistor in series in the circuit. The resistor divides part of the voltage, thereby reducing the voltage flowing through the bulb and making the bulb dimmer. By adjusting the resistance value of the series resistor, different brightness can be achieved.

For easier operation, we can replace the resistor with a potentiometer and adjust the brightness linearly by rotating the knob of the potentiometer. This is the basic principle behind many knob desk lamps.

Although this method is simple and easy to understand, it has obvious defects:

- Low efficiency: The energy consumed by the resistor will be converted into heat, resulting in energy waste.

- Not suitable for high-power LEDs: Heat accumulation may cause component damage and reduce service life.

Another idea is to use an adjustable voltage power supply to control the brightness by adjusting the output voltage. Although the effect is ideal, adjustable power supplies are expensive and large in size, making them unsuitable for home use.

A more efficient method: PWM dimming

Is there a dimming method that is both efficient and suitable for modern LED lighting? The answer is: PWM (pulse width modulation) technology.

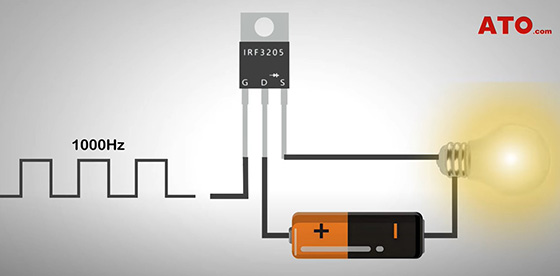

In PWM dimming, we usually use MOSFET (field effect transistor) as an electronic switch. The characteristic of MOS tube is that when the gate is applied with an appropriate voltage, it will turn on (on), otherwise it will turn off (off), and the switching speed is extremely fast, which is very suitable for control scenarios with frequent switching.

We give the MOS tube a periodically changing switching signal (that is, PWM signal), which will quickly turn the bulb on and off at a set frequency. Although this rapid on and off is technically "flickering", if the frequency is high enough, the human eye cannot detect this change.

When the frequency is 1Hz or 2Hz, the bulb flickers noticeably. Increase to 10Hz, the bulb flickers 20 times per second, and the human eye begins to have difficulty distinguishing. Increase to more than 100Hz, and the bulb "looks" like it is continuously glowing. This is because it takes 0.02 seconds for the human brain to sense changes and react. Even if the frequency continues to increase, the naked eye will not feel any changes in the flicker of the bulb. But now we will find that the brightness of the bulb has dropped to half of the original.

How to adjust the brightness of LEDs

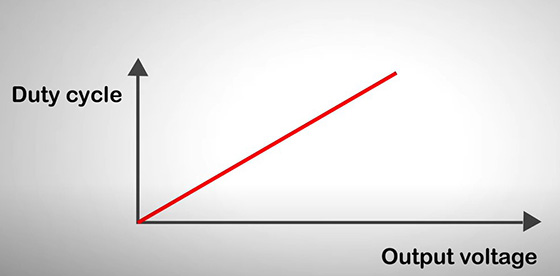

Here we need to introduce a concept, namely pulse width modulation. Pulse width modulation is a technology widely used in the field of electronics. It controls devices by modulating the pulse width in the signal. Specifically, the PWM signal can be regarded as a series of rectangular pulses. Duty cycle is one of the important parameters of the PWM signal. Duty cycle refers to the ratio of the time that the signal is high in a cycle of the PWM waveform to the total cycle. For example:

In a PWM cycle: 50% duty cycle means that the signal is "on" for half of the total cycle; 80% duty cycle means that the signal is "on" for 80% of the total cycle. Changing the duty cycle, that is, the high pulse width of the PWM signal, can adjust the average output voltage. The duty cycle is directly related to the average output voltage: the higher the duty cycle, the higher the output voltage.

We can "average" the voltage output to the bulb by adjusting the duty cycle of the PWM signal, thereby controlling the brightness. This method does not waste electricity to generate heat, and is particularly suitable for high-efficiency LED lighting systems.

In terms of quantitative relationships, the average output voltage is equal to the maximum voltage multiplied by the duty cycle. For example, when the PWM output range is 0~5V: for example, in the output voltage range of 0-5V, the duty cycle is 100%, the PWM signal continuously outputs a high level, and the output voltage is 5V; the duty cycle is 75%, the output voltage is 3.75V; the duty cycle is 20%, the output voltage is 1V; if the duty cycle is 0, the PWM signal continuously outputs a low level, and the voltage is 0V.

This technology can effectively control the flicker and brightness of the lamp. A signal generator can be used to generate a signal. By changing the speed of the PWM signal switch, the switching frequency of the LED lamp can be controlled, affecting the flicker of the LED. By adjusting the duty cycle, that is, the duration of the PWM high-order waveform, the brightness of the LED can be controlled. For example, in the circuit, we input a 1 kHz pulse signal, and the brightness of the bulb depends on the size of the average voltage output by the circuit. The higher the average voltage, the brighter the bulb. Because the duty cycle is directly related to the average output voltage, the LED brightness can be controlled by adjusting the duty cycle of the PWM signal: the higher the duty cycle, the brighter the LED; the lower the duty cycle, the dimmer the LED. The above is the control mechanism of PWM in LED dimming applications.

PWM dimming is not only used in home lamps, but also widely used in electronic projects such as smart lighting, fan control, and motor speed regulation. PWM dimming technology has many advantages. It is not only energy-efficient and can minimize energy waste, but also can accurately control the brightness of LEDs and achieve smooth adjustment from dim light to full brightness. Since PWM is controlled by high-speed switching rather than resistors, the system generates less heat and is more suitable for long-term operation. At the same time, it is highly compatible with various types of LEDs and is suitable for different lighting needs. The circuit structure is relatively simple and the implementation cost is low, so it has been widely used in home lighting, industrial control, and various electronic projects.

Mastering PWM technology is equivalent to mastering the core capabilities of modern electronic control. The next time you turn the knob of a desk lamp, think about whether there is a small PWM circuit working silently behind the scenes? Watch the video below to give you a detailed explanation.