Laser technology in electric car

Electric car is a high-tech car, which is using vehicle power supply as the driving force, integrating vehicle power control and advanced actuation technology, having new technology and new structure. The common electric car includes blade electric vehicle (BEV), extended range electric vehicle (EREV), hybrid electric vehicle (HEV), fuel cell electric vehicle (FCEV) and so on. For these new types of electric cars, people mostly focus on the light weight of the automobile and cruising ability of the battery.

The lightweight technology of the vehicle is considered to an important measure to improve the fuel economy, decrease the contaminant and reduce the carbon emission. The lightweight of the vehicle is to reduce the weight of the vehicle. On the basis of ensuring stability and promoting the performance, various assembly components are energy-saving designed, so as to optimize the vehicle model continuously. Compared with the traditional resistance welding in the manufacturing link, the laser welding can not only compress the volume of the body structural elements, reduce the weight of the vehicle and decrease its oil consumption. In addition, it can also reduce the working procedure and the material loss, thus improving the producing efficiency.

The automobile manufacturers adopt the advanced steel to weld the on-line laser welding system and employ the fiber laser cutting equipment to conduct deep processing of the auto sheet. The laser welding equipment of tailored blanks has the full-automatic feeding and blanking mechanical arm as well as the full-automatic workpiece matching organism. Coordinated with the fiber welding connection and welding seam tracking system, it is mainly used to process the metal material products and the sheet workblank of the inner and outer surface of the automobile (with or without uniform thickness). The annual output can reach 1.8 million pieces per year.

The laser cutting machine employs the gantry structure, with bilateral gear rack and bilateral drive. It has the characteristics of stable structure, good rigidity and high speed. Its positioning speed can reach more than 100m/min. It can realize the mixed routing manufacturing of different vehicle models, quick positioning of the body in white, laser braze, integrated technology of the welding and carrying industrial robot applications and so on. Compared with the traditional technology, the production efficiency has improved 20% and the body rigidity has improved 30%, thus promoting the production efficiency and product quality greatly.

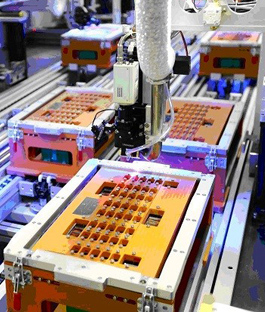

As the core component of the electric car, the battery has always been regarded as the important symbolic technology of the development of the electric car. It is also the bottleneck of restricting its development. Its performance has direct influence to the endurance length of the electric car. Various spontaneous combustion accidents of the electric cars also make the consumers rather scared. Because of the numerous welding positions, great welding difficulty and high precision demand of the electric battery, the traditional welding means can't reach the requirements.  However, if the laser welding technology is used into the power battery welding field, it can improve the safety and reliability of the battery, so as to prolong its operation life because of the small loss of welding material, less deformation of the welded workpiece, stable device performance and easy operation, high welding quality and automatic degree. As an integration and manufacturing process of gathering the anode and cathode materials, membrane and electrolyte as well as other raw materials into a whole, it is the key technology of the whole power battery manufacturing process. In the area of manufacturing the power battery, the manufacturers combine the laser welding technology and automation as well as the intelligent system, thus establishing the full-automatic sealing line of the power battery of the automobiles. Through reading the bar code to recognize the product categories, it will complete the automatic vacuum extraction, washing the welding area with laser, automatic sealing and spot welding, continuous welding and after-welding inspection successively, so as to promote the electric car to march toward intelligent manufacturing with the automatic production line.

However, if the laser welding technology is used into the power battery welding field, it can improve the safety and reliability of the battery, so as to prolong its operation life because of the small loss of welding material, less deformation of the welded workpiece, stable device performance and easy operation, high welding quality and automatic degree. As an integration and manufacturing process of gathering the anode and cathode materials, membrane and electrolyte as well as other raw materials into a whole, it is the key technology of the whole power battery manufacturing process. In the area of manufacturing the power battery, the manufacturers combine the laser welding technology and automation as well as the intelligent system, thus establishing the full-automatic sealing line of the power battery of the automobiles. Through reading the bar code to recognize the product categories, it will complete the automatic vacuum extraction, washing the welding area with laser, automatic sealing and spot welding, continuous welding and after-welding inspection successively, so as to promote the electric car to march toward intelligent manufacturing with the automatic production line.