Level Sensor Basics

Level sensors play a critical role in modern automation systems. Whether in water treatment plants, chemical facilities, food processing lines, or residential water, accurate level measurement ensures safe operation and stable process control. This article will introduce the basic knowledge of level sensors.

I. What is a Level Sensor?

A level sensor is a device used to detect and measure the level of substances such as liquids, powders, and granular materials inside tanks, containers, or pipelines. It monitors the quantity of material present and identifies whether it has reached a specified level. Widely applied in water treatment, chemical processing, oil and gas, food production, agriculture, and industrial automation, level sensors help ensure safe operation, prevent overflow, and support reliable automatic control.

II. Working Principle

Although different level sensors use various sensing technologies, their fundamental working principle is essentially the same. At its core, a level sensor operates based on feedback and control.

1. Level Detection and Signal Conversion

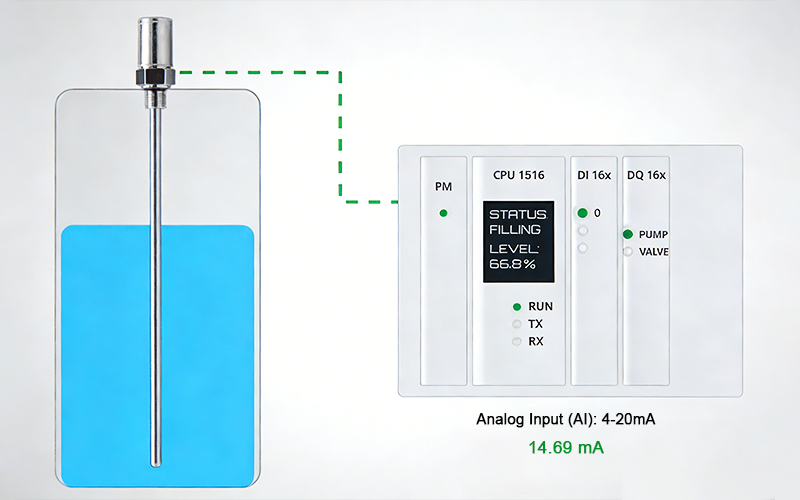

The process begins when the sensor detects the current level of liquid or bulk material inside a tank, vessel, or silo. Once the level is detected, the sensor converts this physical measurement into an electrical signal.

In industrial applications, the most common output formats include:

- 4–20 mA current signals (widely used in industrial automation due to strong anti-interference capability and long-distance transmission stability)

- Voltage signals

- Digital signals

- simple on/off switch outputs (commonly used for point level detection)

2. Signal Comparison by the Control System

The output signal is sent to a control system, typically a PLC (Programmable Logic Controller) or other industrial controller.

The controller compares the actual measured level with a preset target value (setpoint). This comparison determines whether the current level is within the acceptable operating range.

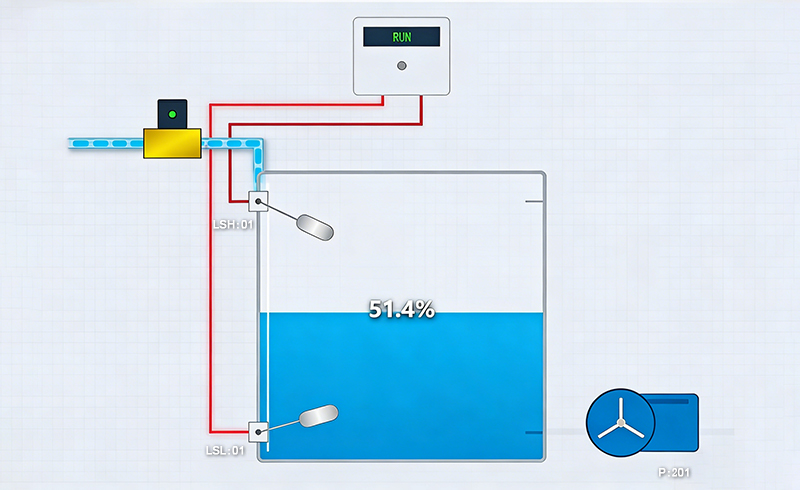

3. Control Action Based on Deviation

If a difference exists between the measured level and the preset target, the controller takes corrective action:

- If the level is too low, the system may start a pump or open a feed valve to fill the tank.

- If the level is too high, it can shut off an inlet valve or activate an alarm to prevent overflow.

It is important to emphasize that level sensors do not directly control pumps, valves, or alarms. Their role is to provide accurate and continuous level data. The control system interprets this data and executes the appropriate response.

Through continuous detection, signal transmission, comparison, and corrective action, the entire process forms a closed-loop control system. This closed-loop mechanism ensures automated, stable, and reliable level management, reducing manual intervention.

III. Common Types

There is no universal sensor that works for all scenarios. Different applications require different technologies, such as capacitive, ultrasonic, radar, float, each suited to specific media, temperatures, pressures, and installation conditions.

Here are some common types of level sensors:

- Capacitive Level Sensor: Detects changes in capacitance caused by the presence or absence of liquid or solid materials. Suitable for both conductive and non-conductive media in various industrial applications.

- Radar Level Sensor: Uses microwave signals to measure material level with high accuracy and strong stability. Commonly applied in demanding industrial environments, including high temperature, high pressure, or dusty conditions.

- Ultrasonic Level Sensor: Measures the distance to the material surface using ultrasonic sound waves. Ideal for non-contact level measurement and suitable for corrosive or harsh environments.

- Float Level Sensor: Operates with a buoyant float that rises and falls according to the liquid level. Widely used in water tanks, sump systems, and pump control applications due to its simple and reliable structure.

To learn more about the different types of sensors, how they work, and their good and bad points, click here to watch the comparison video.

IV. Applications

Level sensors are used across virtually every industry.

- Water treatment: Control pumps and chemical dosing

- Food and beverage industry: Manage ingredients in mixing tanks

- Chemical plants: Ensure safe batching and reactor control

- HVAC systems: Monitor boiler water and condensate tanks

- At home: Control your water pump or washing machine

They ensure process integrity, safety, and automation everywhere.

V. Conclusion

Level sensors are essential components in modern process control systems. Regardless of the sensing technology used, their purpose remains the same: to provide accurate, reliable level data that supports automated control. For more details, click the link below.

Choosing the right level sensor ensures stable performance, improved safety, and long-term operational efficiency across a wide range of industrial and residential applications. With dependable quality and professional specifications, ATO supports diverse level sensors needs. You are welcome to visit ATO level sensor catalog to explore suitable level sensor for your project.