What is an Inertial Measurement Unit (IMU)?

An Inertial Measurement Unit (IMU) is an electronic device that uses inertial sensing technology to measure an object's three-axis attitude (or angular rate) and acceleration. It acts like a device's "inner ear" and "balance system," capable of determining its own motion state in space through self-sensing without external signals (such as GPS or Wi-Fi). From smartphones in our pockets to drones soaring in the sky, and spacecraft exploring the unknown, the IMU is a core component for achieving autonomous navigation, attitude stabilization, and motion tracking.

How an IMU Works

The core working principle of an IMU is based on the law of inertia in classical physics. It continuously senses its own motion changes through multiple integrated sensors.

Its workflow can be summarized as: from sensing to data processing, and finally, information output. The accelerometer inside the IMU measures specific force, which is the acceleration of an object relative to free fall; it includes the vector sum of gravitational acceleration and kinetic acceleration. The gyroscope measures the angular velocity of rotation around various coordinate axes using principles such as the Coriolis force. The raw data collected by these sensors are typically analog or digital signals with noise and temperature drift. This data is then transmitted to a microprocessor, where it undergoes filtering, calibration, and compensation algorithms to ultimately output relatively clean and usable physical quantities such as acceleration and angular velocity.

In some applications, this data is integrated using more complex inertial navigation system (INS) algorithms to calculate the object's velocity, position, and attitude angles.

Types of IMUs

Based on their structural precision and number of axes, IMU products can be mainly classified into the following categories:

Classification by Structure

Discrete IMUs: Early IMUs used separate, relatively large mechanical components for sensors such as accelerometers and gyroscopes, commonly found in high-end military and aerospace fields.

Modular IMUs: Integrating multiple sensor chips onto a single circuit board is the most common form today, widely used in consumer electronics and industrial fields.

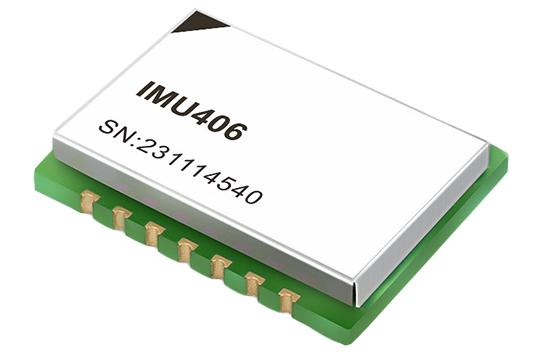

Micro-Electro-Mechanical Systems (MEMS) IMUs: This is the most mainstream type today. Utilizing MEMS technology, it shrinks sensor size to the chip level, offering significant advantages such as small size, light weight, low cost, and low power consumption, enabling its widespread adoption in consumer products such as smartphones and wearable devices.

Classification by Number of Axes

3-axis IMUs: Typically containing only one set of three-axis accelerometers or one set of three-axis gyroscopes, they can only measure linear acceleration or angular velocity in three degrees of freedom. Their function is relatively simple and cannot fully describe the three-dimensional motion attitude of an object. They are commonly found in simple devices that only need to detect vibration or tilt angles.

6-axis IMU: Currently, the most mainstream in consumer electronics. It integrates a three-axis accelerometer and a three-axis gyroscope, capable of simultaneously measuring linear acceleration and angular velocity in three dimensions. It is widely used in smartphones, drone attitude stabilization, and consumer VR devices. However, 6-axis IMUs inherently suffer from integral drift in yaw angle calculation.

9-axis IMU: Adding a three-axis magnetometer to the 6-axis IMU, it can calculate absolute and drift-free roll, pitch, and yaw angles, achieving complete and accurate measurement of object attitude. Therefore, it has become an indispensable core sensor in high-end drones, robots, and augmented reality devices.

10-axis IMU: Integrating a barometer on top of the 9-axis IMU architecture. The barometer estimates relative altitude by measuring atmospheric pressure, enabling devices equipped with 10-axis IMUs (such as high-end drones and outdoor sports watches) to achieve precise altitude hold and floor positioning.

What Does an IMU Measure?

The core task of an IMU (Integrated Measurement Unit) is motion sensing. It directly measures two key physical quantities using two sets of sensors:

- A Three-axis Accelerometer: Captures the linear acceleration of an object in the X, Y, and Z directions to determine the device's movement status.

- A Three-axis Gyroscope: Measures the angular velocity around the three axes to determine attitude changes such as roll and tilt.

However, this raw data contains errors and cannot be used directly. Therefore, it must be processed using data fusion algorithms (such as Kalman filtering). This process effectively compensates for errors and "enhances" the data, ultimately calculating the three-dimensional attitude angles we intuitively need—roll, pitch, and yaw.

In short, the IMU "senses" acceleration and angular velocity, and then, through algorithmic "interpretation," outputs precise attitude information for navigation and control.

Applications of IMU

IMUs have extremely wide applications, covering almost all modern fields that require motion and attitude sensing:

- Consumer Electronics: Smartphone screen auto-rotation, pedometers, motion-sensing control in game controllers, and head movement tracking in VR/AR headsets all rely on IMUs.

- Drones and Robotics: IMUs are central to drones' flight attitude stabilization, autonomous hovering, and precise control. For robots, help maintain balance and perform path estimation.

- Transportation: Electronic Stability Programs (ESP) in automobiles, airbag deployment systems, and increasingly prevalent autonomous driving technologies all depend on IMUs to sense sharp turns, skidding, or collisions.

- Industry and Energy: Used for attitude monitoring of construction machinery, motion control of industrial robots, and pitch adjustment of wind turbine blades.

- Aerospace and Defense: This is the birthplace and highest-end application area of IMU technology, used in inertial navigation systems for aircraft, missiles, satellites, and spacecraft to ensure accurate navigation in any environment.

- Personal and Sports: Motion monitoring (running, swimming), golf swing analysis, and athlete motion capture and skill analysis in smart bracelets/watches.

From basic posture sensing to precise absolute position and altitude measurement, the IMU is a core sensor connecting physical motion and the digital world, making its technology and selection crucial. Whether your project is in the prototype development stage or requires large-scale production, the ATO industrial automation shop provides comprehensive support. Our platform brings together a wide range of IMU products, from consumer-grade to industrial-grade to tactical-grade, covering a broad range of accuracy to meet the demanding needs of various fields such as drones, robots, smart wearables, and industrial automation. We not only provide high-quality hardware but also offer professional technical selection guidance and algorithm support to help you accurately identify product needs and quickly turn your ideas into reality. Welcome to visit the ATO platform to learn more and choose the IMU that best suits your needs!