Capacitive Level Sensor vs. Radar Level Sensor

In modern industrial automation control systems, liquid level measurement is an indispensable and critical component. Faced with the vast array of liquid level measurement technologies available on the market, selecting the most suitable sensor presents a significant challenge for many. As two mainstream technologies, capacitive and radar level sensors each possess unique advantages and limitations. This article will provide a detailed comparison to help you make an informed decision.

Working Principle

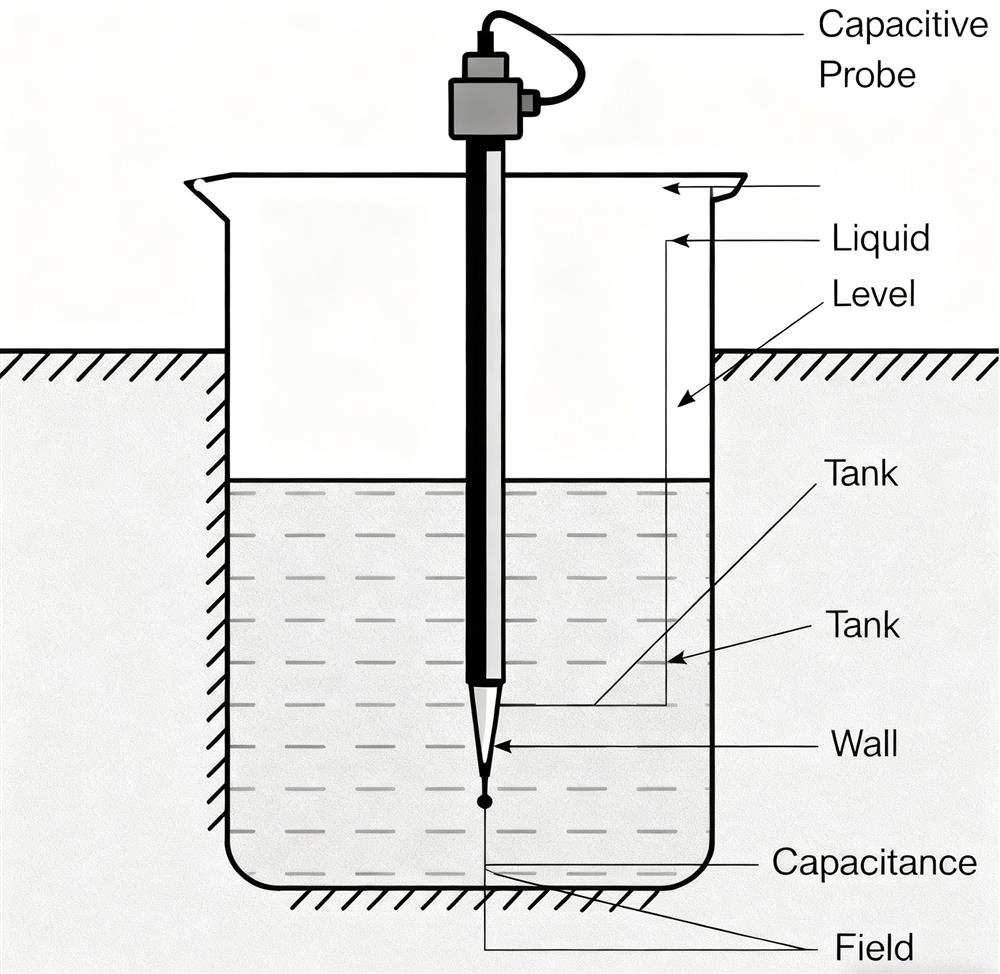

Capacitive level sensor: operates based on the electrical properties of the medium. When the sensor probe and the liquid or granular material in the container form a capacitor, changes in the liquid level cause corresponding variations in capacitance. This measurement principle requires the capacitive sensor to be in direct contact with the measured medium, and its accuracy largely depends on the stable dielectric constant of the medium. Capacitive sensors perform reliably with conductive liquids such as water and with non-conductive liquids exhibiting a stable dielectric constant.

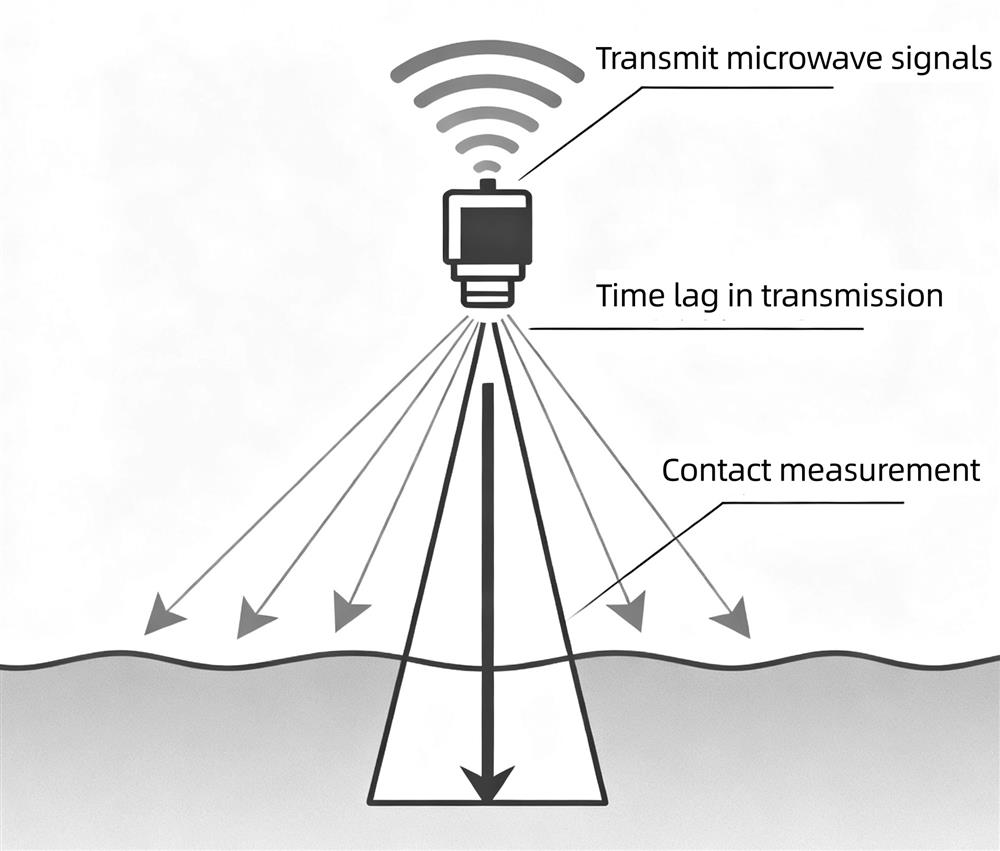

Radar level sensor: employs a fundamentally different working principle. They emit microwave signals toward the liquid surface and accurately calculate the liquid level by measuring the time difference between signal transmission and return. This non-contact measurement method allows the sensor to perform without touching the medium, effectively avoiding issues such as medium contamination, corrosion, or adhesion. The propagation characteristics of radar waves make them nearly immune to environmental factors like medium density, viscosity, temperature, pressure, steam, and dust, ensuring stable and reliable measurement even in complex working conditions.

Performance Comparison

Measurement Range and Depth

Capacitive: Typically suited for short to medium-range measurements. Performance decreases in very deep tanks or silos due to signal attenuation.

Radar: Excel in long-range measurements, often exceeding 30–80 meters depending on model. Ideal for tall vessels, silos, and outdoor tanks.

Accuracy and Repeatability

Capacitive: Provides good accuracy when the dielectric constant of the medium is stable. However, accuracy can drift if process conditions vary. Repeatability is solid under controlled conditions.

Radar: Highly accurate, with errors often within a few millimeters. Accuracy is maintained regardless of changes in temperature, pressure, vapor, or turbulence.

Response Time

Capacitive: Fast response time since changes in capacitance are detected almost instantly. Suitable for applications requiring quick detection of rising or falling levels.

Radar: Also provides quick response, but advanced signal processing can slightly delay output compared to capacitive sensors. Still suitable for most dynamic processes.

Media Compatibility

Capacitive: Performed well with liquids and some powders, provided they have sufficient dielectric contrast with air. May struggle with hydrocarbons, oils, or media with low permittivity.

Radar: Worked across almost all liquids, slurries, and bulk solids, regardless of dielectric constant. Handles foams, vapors, dust, and even turbulent surfaces with consistent performance.

Environmental Robustness

Capacitive: Sensitive to coating, buildup, and contamination on probes, which can cause false readings or require frequent cleaning. Performance is influenced by temperature and pressure changes.

Radar: Highly robust in harsh environments. Resistant to steam, vapor, foam, and dust. Non-contact versions have no direct contact with media, reducing contamination and wear.

Signal Reliability

Capacitive: The signal may weaken or drift when the dielectric constant of the medium changes. Requires careful calibration and compensation for changing conditions.

Radar: Stable and reliable signals due to advanced microwave processing. Multiple frequency options help minimize interference and optimize reflection from different surfaces.

Maintenance and Lifespan

Capacitive: Probes require periodic cleaning, especially in sticky or corrosive media. Over time, coatings can degrade performance.

Radar: Non-contact radar requires minimal maintenance. Longer lifespan due to reduced exposure to harsh materials.

| Feature | Capacitive Sensors | Radar Sensors |

| Cost | Cost-effective | Higher cost upfront |

| Structure | Simple design | More complex system |

| Response Time | Very fast for stable media | Fast, slightly slower due to processing |

| Range | Limited to short/medium | Long range, ideal for tall tanks |

| Accuracy | Good under stable conditions | High accuracy, unaffected by environment |

| Environmental Tolerance | Sensitive to buildup, temp, pressure | Robust against steam, dust, and foam |

| Maintenance | Needs probe cleaning | Minimal maintenance |

| Best Use Case | Small tanks, stable liquids, budget projects | Harsh environments, long tanks, precision needs |

How to Choose?

Selecting the right level sensor requires balancing media properties, operating conditions, and accuracy needs.

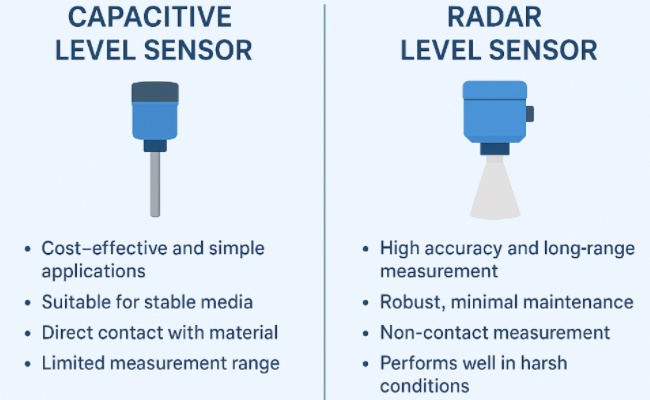

- Media compatibility: Capacitive sensors require stable dielectric constants and suit water or oils. Radar sensors perform independently of media characteristics, ideal for adhesive or corrosive liquids.

- Work environment: Radar is preferred in challenging conditions like steam or dust. Capacitive sensors offer cost efficiency in stable settings with maintenance access.

- Accuracy and cost: Radar ensures ±1mm precision for custody transfer. Capacitive sensors provide economical monitoring for non-critical applications, factoring in calibration needs.

Conclusion

Capacitive and radar sensors are both essential solutions in modern level measurement. Capacitive sensors excel in cost-effective and straightforward applications with stable media, while radar sensors demonstrate superior accuracy, long-range capability, and resilience in harsh conditions. A clear understanding of their performance differences and ideal use cases will help you make the right choice for your process control needs. Explore our full range of level sensors at ATO and find the best model for your application today.