Gear motors and cycloidal motors are two different types of motors, both serving the purpose of better speed regulation, but they differ considerably in appearance, principle of operation, purpose, construction, and principle of operation, resulting in different performance and applications. The following are their main differences.

Tag: gear motor

ATO offers a diverse range of spur gear motors, planetary gear motors and worm gear motors with power options falling between 30W and 2000W, voltage between 12V and 48V DC, torque between 0.1Nm and 300Nm, providing you with highly efficient gear motor solutions that can meet any application requirements.

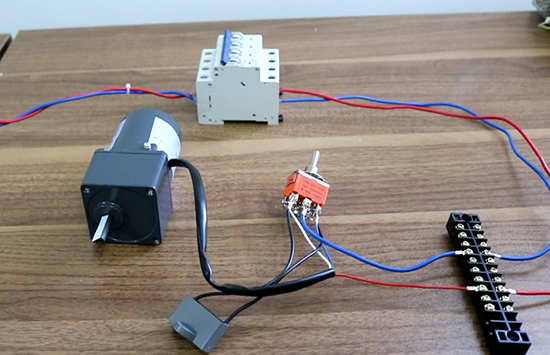

What we have here today is a 30W DC gear motor that operates at 24V and 1 to 60 gear ratio.

The gear motor refers to the reducer and the motor. It can be divided into DC geared motors and AC geared motors. It is widely used. You may encounter work abnormalities in daily life. Let's take a look at the troubleshooting of the geared motor.

The planetary geared motor is the same as other geared motors. It needs to be lubricated when it is running. This will not only speed up the operation of the planetary gear motor, but also ensure its normal operation. How to properly lubricate your planetary gear motors?

The planetary gear motor is an industrial product with a wide range of uses, which can reduce the speed of the motor and increase the output torque at the same time. It has a variety of specifications to choose from, including 2 or 3 stage planetary gears, which can be combined with different types of primary gears. It can also be used as an accessory in industries such as lifting, excavation, transportation, and construction.

A gear motor is a power transmission machinery, which is used by all levels of gear transmission to achieve the purpose of speed reduction. Many transmission equipments want to achieve the effect of low speed and high torque is used is the gear reducer, the use of gear speed converter to decelerate the number of revolutions of the motor to the required number of revolutions, and get a larger torque mechanism.

The gear motor is a widely used reduction drive equipment, and the drive structure is assembled by a drive motor and a gear box, also known as a "reducer". There are many types of drive motors. DC motors, brushed motors, brushless motors, stepper motors, coreless motors, and servo motors can all be used as drive motors. The gearbox can adopt planetary gearboxes, cylindrical gearboxes, parallel gearboxes, worm gearboxes, screw gearboxes, and so on. Depending on the different drive motors, it can be divided into DC gear motors, stepping geared motors, brushed gear motors, brushless gear motors, hollow cup geared motors. It also can be divided into planetary gear motor, gear reducer, worm gear motor, parallel gear reducer, screw gear reducer according to the structure of the gearbox. Reducer motors with different structures have different application characteristics.

Gear motor is an integrated device of speed reducer and electric motor, also known as gear reduction motor. Professional manufacturers integrate and assemble the gearbox and electric motor to be a set for sale. Gear motor is a unit for connection, transmission, speed reduction, and increasing torque. AC/DC gear motors have the advantages of low energy consumption, superior performance, small size, compact structure, reliable and durable, etc.

According to speed, a motor itself can be divided into low speed (low rpm) motor and high speed (high rpm) motor. According to functions, there are drive motors and control motors. No matter what kind of motor, there is a rated speed and torque. To obtain variable speed, a dedicated controller or speed regulator is needed to control the speed, but this will increase a certain cost and cause the motor price to become higher. On the other hand, performance of the motor after speed regulation will decrease to varying degrees. In this case, gear motor can perfectly solve this problem.

ATO AC gear motor is composed of a single phase AC torque motor and a gearbox, which has high starting torque and sloping characteristics, allowing speed control simply by changing the voltage of the power supply. The special rotor provides excellent performance for holding, winding, andtensioning applications. Next, we will introduce how to wire and test a ATO AC torque motor with gearbox?

Oil leakage is a common problem for gear motor, and the problem may be caused by box quality, lubricating oil quality, oil seal quality and air pressure outside and inside the box. Meanwhile, excessive lubricating oil will also lead to oil leakage. Once the oil leakage occurs in the gear motor, corresponding measures should be taken, and this paper ATO will introduce the solutions for stopping gear motor oil leakage.

Gear motor is widely used in the metallurgy, mine, light industry, chemical industry, steel industry, cement, printing, sugaring, food industry, construction, lifting transportation and fan industry. Working environment of these industry may be damp, and damp environment will directly affect the operation of gear motor. How to keep your gear motor dry when works in such a damp environment?