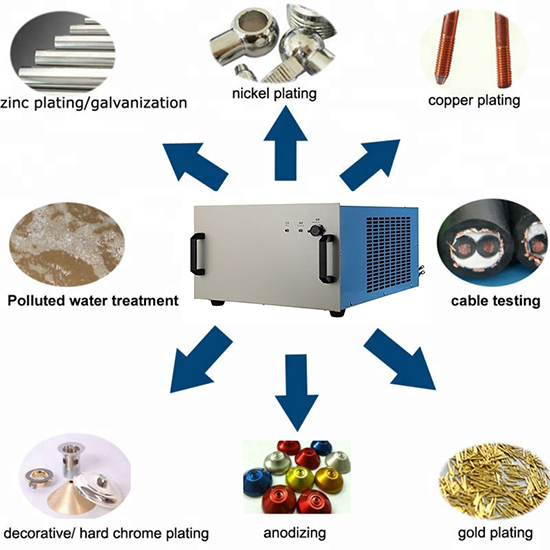

How Plating Rectifier Works in Plating Process?

The plating rectifier adopts high frequency switching pulse technology and has the reasonable product structure and strong reliability. Because of its small size, light weight, high efficiency and high reliability, the power supply has become a new generation of silicon controlled rectifier and has been widely used in various plating solutions in the electroplating industry. Electroplating process includes four aspects: Electroplating solution, electroplating reaction, electrode and reaction principle, and electrodeposition process of metal.

1. Electroplating solution

There are six elements of electroplating solution: Main salt, complexing agent, additional salt, buffering agent, anode activator and additive.

2. Electroplating reaction

Electrochemical reaction in plating reaction: The part to be plated is the cathode, which is connected to the negative electrode of the DC plating rectifier power source. The metal anode is connected to the positive electrode of the rectifier. Both the anode and the cathode are immersed in the plating solution. When a certain potential is applied between the anode and the cathode, a reaction occurs at the cathode: Metal ions Mn diffused from the inside of the plating solution to the electrode and the plating solution interface obtain n electrons from the cathode and reduce to metal M. On the other hand, a completely opposite reaction occurs at the anode, that is, the metal M is dissolved at the high-frequency switching power supply at the anode interface, and n electrons are released to generate metal ions Mn.

3. Electrode and reaction mechanism

A. Electrode potential

When a metal electrode is immersed in a solution containing the metal ion, the following equilibrium exists: the reaction where the metal loses electrons and dissolves in the solution and the reverse reaction where the metal ion gains electrons to precipitate the metal should coexist. In order to accurately compare the effect of the nature of the substance on the equilibrium potential, it is stipulated that when the solution temperature is 250℃ and the concentration of metal ions is 1mol/L, the measured potential is called the standard electrode potential. Metals with a large negative electrode potential are liable to lose electrons and oxidized, while metals with a large positive electrode potential will obtain electrons easily and get restored.

B. Polarization

The so-called polarization refers to the phenomenon that the electrode potential deviates from the equilibrium electrode potential when a current passes through the electrode. Therefore, the current-potential curve is also called a polarization curve. The main causes of polarization are electrochemical polarization and concentration polarization.

(1). Electrochemical polarization. Because the speed of the electrochemical reaction on the cathode is less than the speed of the electrons supplied by the external power source, the electrode potential moves in a negative direction and causes polarization.

(2). Concentration difference polarization The polarization due to the difference between the concentration of the liquid layer near the surface of the electrode and the concentration of the solution body is called concentration polarization, which is caused because the diffusion speed of the ions in the solution is smaller than the speed of the electron movement.

4. Electrodeposition process of metal

The electroplating process is a process in which metal ions in a plating solution are reduced to metal atoms by an electrode reaction under the action of an external electric field, and metal deposition is performed on a cathode.

In short, the working principle of plating rectifier in electroplating process is: In the salt solution containing the metal to be plated, the substrate metal to be plated is used as the cathode, and the cations to be plated in the plating solution are deposited on the surface of the substrate metal by electrolytic action, so as to form a plating layer.