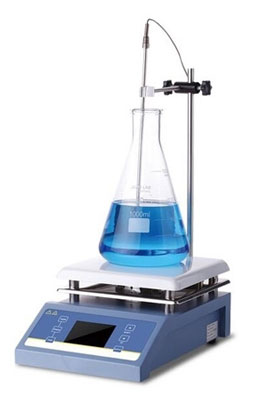

How to Maintain Magnetic Stirrer Life?

Magnetic stirrers are usually used in food, biopharmaceutical and other fields. As biopharmaceuticals put forward higher requirements for the sterility and risk control of the agitator shaft seal, industrial magnetic agitators came into being in Sweden in the 1980s. Magnetic stirrers have become the mainstream of the market, and continue to develop in the direction of simplicity, high torque, high shear force or very low shear force, safe bearing materials, easy online cleaning, and online sterilization. For example, a magnetic stirrer for bioreactors, a magnetic stirrer for high-shear homogenization, etc. Whether it can prove that the agitator can be cleaned and sterilized online, and the bearing material safety has become the gold standard before the selection of biopharmaceutical agitators.

- Maintenance and precautions for magnetic stirrer

- Do not let the instrument work without heating the liquid.

- Before operating the hot plate magnetic stirrer, check whether it is grounded or not, and make sure that it can work only after it is completed.

- In order to ensure that the magnetic stirrer is not damaged, insulating materials are usually placed inside the magnetic stirrer. Therefore, when we use the magnetic stirrer, we will find a little white smoke or a pungent smell. These are normal phenomena. It's not a product quality problem, just keep ventilation.

- The internal components of the magnetic stirrer have an upper limit for heating, so the method must be considered when heating is to ensure that the machine is not heated only, and remember to change the state of the motor to a rotating state, so that it can be protected well magnetic stirrer.

- After the heating work is completed, you must remember to turn off the heating first, wait a few minutes before the temperature has dissipated, and then turn off the stirring. To

- Ensure that the operating environment is dry, because in a humid environment, the magnetic stirrer is likely to cause leakage and other phenomena. This is why the instrument must be grounded. If the instrument is very humid, it must be dried with hot air.

- Be careful during operation, because the temperature is generally relatively high.

- For the sake of safety, there is a fuse on the back of the magnetic stirrer. You can check whether it needs to be replaced when the device is still not working after it is powered on.

- As long as you pay attention to the use and maintenance when using the magnetic stirrer, it will definitely extend the service life of the equipment and make the equipment work for us better.

This is all about how to maintain magnetic stirrer life, and if you still want to consult more information about ATO magnetic stirrer, welcome to leave a message in the comment section.