How to Troubleshoot Magnetic Stirrer?

A magnetic stirrer is a device that forces liquid and gas media to convect and mix uniformly. The type, size, speed, power and other parameters of the agitator have an important impact on the effect of media stirring and mixing. Different stirring processes need to be realized by the operation of different stirring devices. When selecting the type, first of all, the purpose and requirements of the stirring operation should be based on the process. The following is an introduction that how to troubleshoot magnetic stirrers.

When the magnetic stirrer fails, do not rush to do it first, but first ask the process of the failure and the failure phenomenon. For unfamiliar equipment, you should be familiar with the circuit principle and structural characteristics first, and abide by the corresponding rules. Before disassembly, be fully familiar with the function, position, connection method and relationship with other surrounding components of each electrical component.

When the magnetic stirrer fails, do not rush to do it first, but first ask the process of the failure and the failure phenomenon. For unfamiliar equipment, you should be familiar with the circuit principle and structural characteristics first, and abide by the corresponding rules. Before disassembly, be fully familiar with the function, position, connection method and relationship with other surrounding components of each electrical component.- When the equipment is not powered on, judge the quality of the buttons, transformers, thermal relays and fuses of the electrical equipment, so as to determine the fault location. Power-on test, listen to the sound, measure parameters, judge the fault, and then carry out maintenance. For example, when the motor is out of phase, if the three-phase voltage value cannot be judged, you should listen to the sound and measure each phase-to-ground voltage separately before judging which phase is defective.

- Only after confirming that the mechanical parts are fault-free, conduct electrical inspections. When checking the circuit fault, the detection instrument should be used to find the fault location. After confirming that there is no bad contact fault, the operation relationship between the circuit and the machine should be checked in a targeted manner to avoid misjudgment.

- The gearbox of the magnetic stirrer has high machining accuracy and good heat treatment. Thoroughly clean the gearbox and carefully check the gears, gear shafts and bearings. It is found that the surface of the gear teeth is smooth, without pitting corrosion and intermingling, the gear meshing backlash is normal, and the tooth profile has no obvious wear, the radial and axial clearances of each bearing are normal, and there are no pitting spots on the inner and outer rings and roller surfaces, and the overall quality is good. The axial clearance of each shaft is reasonable, and the output shaft of the hand plate can move freely, without jamming and abnormal noise. Then, the fault of the gearbox can be ruled out.

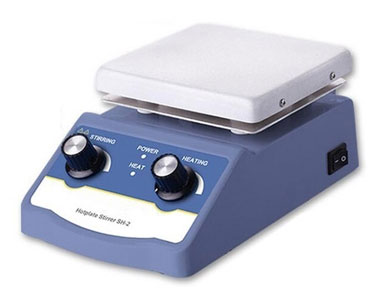

The magnetic stirrers provided by ATO.com are used for liquid mixing, mainly for stirring or simultaneously heating and stirring liquids or solid-liquid mixtures with a certain viscosity. 1L, 3L, 5L laboratory hot plate magnetic stirrer, heating mantle with magnetic stirrer and digital heating mantle with stirrer for your choices, shop online now!