What does a Force Sensor Do?

A force sensor is a device that converts the magnitude of the force acting on it into a measurable electrical signal (such as voltage or current). Simply put, it acts as a translator, translating the physical quantity "force" into a signal that electronic systems can "interpret."

Force sensors are one of the most core sensor types in the measurement field, widely used in various fields from industrial manufacturing to scientific research.

- Core Working Principle of Force Sensors

- Main Types of Force Sensors

- How to Choose a Force Sensor?

- Main Application Areas of Force Sensors

- Force Sensor Vs. Load Cell

- ATO Force Sensors for Sale

Core Working Principle of Force Sensors

The core operating principle of a force sensor combines classical physics with precision electronics. Most force sensors rely on the synergy of strain gauges and Hooke's law.

Inside the sensor is a metal structure called an "elastic body," which deforms slightly when an external force acts on it. Strain gauges attached to strategic locations on the elastomer are then stretched or compressed, causing their resistance to change slightly. This change is keenly detected by a Wheatstone bridge circuit and converted into a weak voltage signal. After being amplified by an amplifier, it is read by a data acquisition system or controller. By pre-calibrating the system with a known force value, the system can establish a precise correspondence between the signal and the force value, achieving high-precision measurement.

Main Types of Force Sensors

Force sensors come in a variety of forms depending on the direction and application of the force they measure. They primarily fall into the following categories:

- Compression force sensor: This sensor measures compressive force along an axis.

- Tension force sensor: This sensor measures tensile force along an axis.

- Universal force sensor: This sensor measures both compressive and tensile forces.

- Bending moment and torque force sensor: This sensor measures rotational torsion or bending moment.

This versatility enables them to be used in a wide range of applications, from simple weighing to complex mechanical analysis.

How to Choose a Force Sensor?

When selecting a force sensor, consider the following key parameters:

- Range: The maximum force the sensor can measure (e.g., 500N, 10kN). The chosen range should be slightly larger than the maximum force likely to be encountered in daily measurements to ensure accuracy and longevity.

- Resolution: The smallest force change the sensor can detect. It directly determines whether your measurement system can "see" the changes you want to observe.

- Accuracy: The error range between the sensor output and the actual force value, directly related to the reliability of the measurement results, usually expressed as a percentage of full scale (%F.S.).

- Sensitivity: The ratio of the change in the output signal to the change in the applied force. For example, 2 mV/V means that when a 1V excitation voltage is applied to the sensor, the sensor will output a 2mV voltage signal under full-scale force. This reflects its responsiveness to force changes.

- Overload Rating: The maximum force that the sensor can withstand without being damaged, ensuring that it will not be damaged in unexpected situations. It is usually 150% of the range or even higher.

Main Application Areas of Force Sensors

As a key measuring component, force sensors have a wide range of applications, covering virtually all industrial and technological fields requiring precise force quantification and analysis.

In industrial automation

Force sensors are widely used in robotic gripping operations, ensuring stable gripping and non-destructive manipulation of objects with varying rigidity by real-time detection of gripping force. In automated assembly lines, they precisely monitor the applied force during processes like press-fitting and lamination, providing a key guarantee for consistent product quality.

In the testing and measurement industry

Force sensors are core components of material testing machines, directly determining the accuracy of mechanical properties such as tension, compression, and bending, providing critical data support for material R&D and quality control.

In the aerospace and automotive manufacturing sectors

Force sensors undertake a range of critical measurement tasks, from aircraft engine thrust testing and structural static strength testing to impact force measurement in automotive crash safety performance assessments, providing a reliable basis for design and verification.

In the consumer electronics sector

Force sensing technology is widely used in pressure-sensitive interaction in high-end smartphones and force feedback in game controllers, significantly improving user experience and device interaction performance.

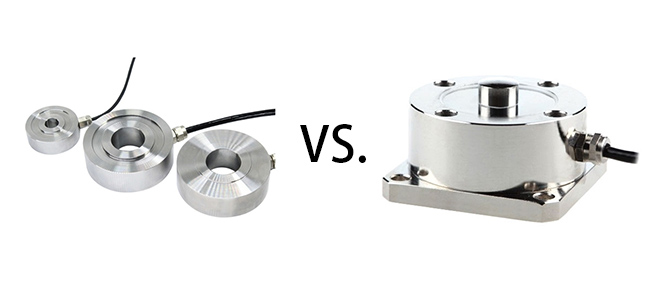

Force Sensor Vs. Load Cell

In the past, people didn't distinguish between load cells and force sensors, referring to them collectively as load cells. Although their technical principles are closely related, the development of weighing technology and the demand for force measurement have led to a growing understanding that they should not be confused. Therefore, in this article, ATO Automation will explain the differences between force sensors and load cells.

I. Core Functions and Physical Nature

Both load cells and force sensors are often based on strain gauge technology, converting mechanical deformation into electrical signals for high-precision measurement. However, the fundamental difference between the two lies in the physical nature of their measurement targets: load cells specifically measure mass, calculating mass by sensing gravity, and their output units are typically kilograms (kg) or tons (t). Force sensors, on the other hand, directly measure force, including tension, compression, shear, and other forces, and their output units are typically Newtons (N) or kilonewtons (kN). While all load cells are force sensors, not all force sensors are suitable for weighing.

II. Calibration Methods and Dependent Conditions

Due to their different measurement targets, the calibration methods for these two types of sensors differ significantly. Load cells must be calibrated in Earth's gravitational field using standard weights of known mass to establish a correspondence between the electrical signal and mass. Therefore, their measurements rely heavily on gravitational acceleration and are extremely sensitive to the verticality of their mounting orientation. Force sensors are calibrated using a standard force gauge to apply a known force, establishing a direct relationship between signal and force. Their measurements are unaffected by gravity, and as long as the force is applied along the sensor axis, the mounting orientation does not affect the accuracy of the results.

III. Typical Application Scenarios

Load cells are primarily used in various weighing systems, such as electronic scales, truck scales, hopper scales, and balances. Their core function is to accurately measure the mass of objects. Force sensors have a wider range of applications, encompassing industrial automation, material mechanical testing, aerospace, and consumer electronics. Typical applications include robot end-point force control, material testing machines, bolt tightening force monitoring, engine thrust testing, and touch feedback for smart devices.

IV. Key Considerations for Project Selection

When selecting a suitable sensor for a specific project, it is important to first determine whether the measurement requirement is mass or force. If the application involves static weighing in the vertical direction, a load cell is preferred. If the measurement requires non-gravity, dynamic, or multiple types of mechanical forces, a general-purpose force sensor should be selected. Furthermore, factors such as range, accuracy, overload capacity, environmental compatibility, and compatible signal conditioning equipment should be considered.

V. Conclusion

Load cells and force sensors, as key components in precision measurement, share the same technological roots, but their core missions and application contexts differ fundamentally due to their distinct functional focuses. Simply put, all load cells are essentially force sensors, but the reverse is not true. A correct understanding of their measurement principles, calibration methods, and application characteristics is crucial for achieving effective and reliable measurement and control. In various industrial and technological applications, the appropriate sensor type should be selected based on the specific measurement object, direction, and system requirements.

ATO Force Sensors for Sale

ATO offers a wide variety of force sensors and load cells, as shown in the table:

| Product | Specs | SKU | Price |

Piezoelectric Force Sensor |

Measuring Range: Sensitivity: Overload Capacity: |

ATO-FS-SACL030LA | $691.19-$1,162.44 |

Compression Force Sensor |

Measuring Range: Sensitivity: Overload Capacity: |

ATO-FS-HX004 | $193.99-$697.24 |

Tension Force Sensor for Thin Film |

Measuring Range: Sensitivity: Overload Capacity: |

ATO-FS-108 | $612.94-$1,084.19 |

Tension Force Sensor for Fiber/Cable |

Measuring Range: Sensitivity: Overload Capacity: |

ATO-FS-TFS500 | $192.47-$663.72 |

Flat Plate Force Sensor for Battery Equipment |

Measuring Range: Sensitivity: Overload Capacity: |

ATO-FS-PB001 | $336.89-$808.14 |

Grip Force Sensor for Hand Strength Test |

Measuring Range: Sensitivity: Overload Capacity: |

ATO-FS-L001 | $499.68-$970.93 |

If you're looking for a solution that delivers precise measurement, reliability, durability, and affordability, we can provide expert product selection advice and technical support to ensure your project achieves the optimal balance between performance, cost, and reliability. Contact the ATO.com store for customized solutions and detailed product information.