With the development of science and technology such as electronic computers, production automation, modern information, military, transportation, chemistry, environmental protection, energy, marine development, remote sensing, and aerospace, the demand for sensors is increasing day by day, and their application fields have penetrated into various industries and in people's daily cultural life. Selecting sensors in these applications can be challenging for any project.

Tag: sensor

A distance sensor is a sensor that uses ultrasonic waves or lasers to measure the distance of an object. It is mainly used to measure the time-varying law of the position of a moving object. It can be used to complete a variety of kinematics and dynamics measurements. A device that measures the distance displacement from the sensor to the object by detecting the amount of physical change of the object using various elements, and converting the amount of change into distance.

The torque sensor calibration device is divided into two categories: dynamic and static. Dynamic torque sensors can also be called torque sensors, torque-speed sensors, non-contact torque sensors, and rotational torque sensors. Torque sensors are the detection of torsional torque sensing on various rotating or non-rotating mechanical components. ATO torque sensors convert physical changes in torque into precise electrical signals. It can be used in the manufacture of viscometers and electric (pneumatic, hydraulic) torque wrenches, with the advantages of high precision, fast frequency response, good reliability and long life.

Laser sensors use focused coherent light to measure the distance to a target object, which are often used to check for the presence of parts. Laser sensors are used in factory automation, typically for products or mechanical parts. The instrument can detect any kind of solid, and the output is proportional to the distance measured, independent of material, color and luminosity. Laser displacement switches are often used to provide high resolution output to provide position or displacement such as PLCs. For enhanced stability, the output signal is usually precise and includes temperature compensation.

Solar radiation is radiant energy emitted by the sun from a nuclear fusion reaction that creates electromagnetic energy. The spectrum of solar radiation is close to that of a black body with a temperature of about 5800 K. About half of the radiation is in the visible short-wave part of the electromagnetic spectrum. The other half is mostly in the near-infrared part, with some in the ultraviolet part of the spectrum.

Solar radiation sensor is designed on basis of silicon-cell principle. It is mainly used for measuring solar radiation within 300-1100nm wavelength. If the sensing face is downwards, it can test the reflected radiation and solar radiation on the incident to the inclined plane. PAR sensor is mainly used for measuring solar radiation within 400-700nm wavelength. It is easy installation and can work continuously in all weathers. When there is sunlight, voltage output proportional to incident light intensity will be generated by the silicon-photo detector in the sensor.

Radiation sensor works by measuring the number of small units of light, known as photons that impact a physical or chemical device located within the instrument. Solar radiation sensors are typically not powered due to the fact that the components located in the device either are influenced by or react to solar radiation in a direct manner.

Radiation sensor adopts photoelectric principle and can be used to measure the total radiation value under sunlight. The radiation sensor uses high-precision photosensitive elements, wide spectrum absorption, high absorption in the full spectrum range, and good stability. A dust cover with a light transmittance of up to 95% is installed outside the sensing element, and the dust cover is specially treated to reduce dust adsorption can effectively prevent environmental factors from interfering with internal components, and can more accurately measure solar radiation.

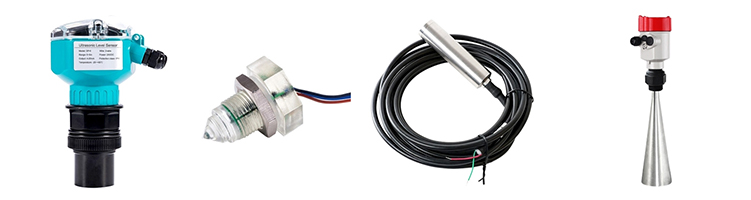

Ultrasonic distance sensors are designed to measure the distance to a remote object through the air without physically touching it. Distance sensors determine this value by emitting high-frequency or ultrasonic soundwaves toward the object being measured, receiving the reflected wave, and calculating the time between emission and reception. While this broad selection makes it possible for customers to find a ultrasonic distance sensor that suits their unique application, it can also make it more difficult to determine which one is right. When we choose ultrasonic distance sensors, we should consider several problems. Here is a brief introduction about what they are.

In the automated production process, liquid level detection and monitoring has always played a more important role, such as the production of food and beverage, daily chemical products, pharmaceuticals, semiconductors and other industries, the cooling and lubrication of various machines, liquid level monitoring directly affects the quality of the product, and even related to the production process can be carried out smoothly.

The application of sensors involves machinery manufacturing, industrial process control, automotive electronics, communication electronics, consumer electronics and special equipment. There are various kinds of voltage sensors, and based on the measuring principle can be divided into Hall voltage sensors, photoelectric isolated voltage sensors, electrically isolated voltage sensors, voltage transformers and so on. Voltage sensors are able to sense the measured voltage and convert it into a usable output signal. In a variety of automatic detection and control systems, voltage sensors often track and collect AC and DC voltage signals that change at high speed. The signals may be high voltage, high current, or weak power with poor load capacity. In these cases, it is necessary to use suitable voltage sensors to collect voltage signals that cannot be directly measured or mismatched, so as to obtain standardized and electrically isolated voltage signals. ATO offers a full range of voltage sensors with different measuring ranges at favorable prices.

Torque sensors are divided into dynamic torque sensors and static torque sensors. The static torque sensor can also be called reaction torque sensor, while the dynamic torque sensor can also be called non-contact torque sensor or rotary torque sensor. Torque sensors are used for detecting the perception of torque on various rotating or non-rotating mechanical components. The torque sensor converts the physical changes of torsion into precise electrical signals. The torque sensor has the advantages of high precision, fast frequency response, good reliability and long life. ATO has many better torque sensors for sale.

Common torque sensors are measured using bonded strain gauge technology, where the strain gauge is bonded to a suitably designed shaft. It features a circular shaft and a strain gauge torque sensor for 45 degrees applications. This design has been around for years. However, the design and configuration of the device will be determined by the application, the shaft can be solid or hollow, and the cross section can be different from cross, square or other custom designs in order to obtain maximum signal output. Shear stress is caused when torsion is applied to an axis causing it to distort.

Liquid level sensor is a pressure sensor for measuring liquid level. Static pressure input liquid level transmitter is based on the principle that the measured liquid static pressure is proportional to its height. It adopts foreign advanced isolated diffused silicon sensor or ceramic capacitor pressure sensor to convert the static pressure into electrical signal, and then into standard electrical signal (generally 4 ~ 20mA / 1 ~ 5VDC) after temperature compensation and linear correction. The level sensor can be divided into contact level sensor and non-contact level sensor.

We live in a world of sensors. They are everywhere. You can find them in our homes, offices, hospitals, etc. They can make our lives more convenient and easy by detecting our presence to turn on lights, regulate room temperature, detect smoke or fire, and many other tasks. In this article, ATO will make a detailed introduction from four aspects: the definition of sensor, different types, application and how to choose a right sensor.

There are many definitions of sensors. Generally speaking, a sensor is a detection device, which can sense the measured information, and can transform the perceived information into electrical signals or other required forms of information output according to certain rules, so as to meet the requirements of information transmission, processing, storage, display, record and control.

Modern industrial sensors are vastly different in principle and structure, and there are so many different types of products on the market. How can we find the ideal sensor for a specific application? When the sensor is selected, the corresponding measurement method and measuring equipment can be determined. The success or failure of measurement results largely depends on whether the selection of sensors is reasonable.