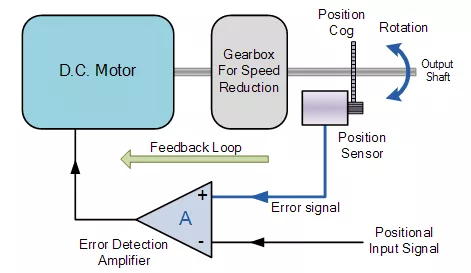

The gear motor is a widely used reduction drive equipment, and the drive structure is assembled by a drive motor and a gear box, also known as a "reducer". There are many types of drive motors. DC motors, brushed motors, brushless motors, stepper motors, coreless motors, and servo motors can all be used as drive motors. The gearbox can adopt planetary gearboxes, cylindrical gearboxes, parallel gearboxes, worm gearboxes, screw gearboxes, and so on. Depending on the different drive motors, it can be divided into DC gear motors, stepping geared motors, brushed gear motors, brushless gear motors, hollow cup geared motors. It also can be divided into planetary gear motor, gear reducer, worm gear motor, parallel gear reducer, screw gear reducer according to the structure of the gearbox. Reducer motors with different structures have different application characteristics.